Table of Contents

Mechanical Rolling ring linear drive in Industrial Automation

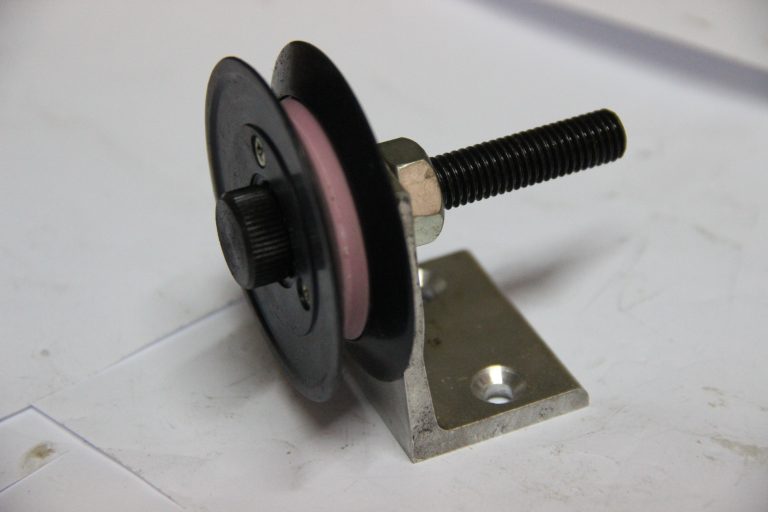

Rolling Ring Linear Drive is a type of linear motion system that is commonly used in industrial automation applications. This technology offers several advantages over other types of linear drives, making it a popular choice for many industries.

One of the key advantages of using a Mechanical Rolling Ring Driver is its high precision and accuracy. This drive system is capable of providing extremely precise positioning and motion control, making it ideal for applications that require tight tolerances and exacting specifications. This level of precision is essential in industries such as manufacturing, where even the smallest deviation can result in costly errors or defects.

In addition to its precision, Mechanical Rolling Ring Linear Drive also offers excellent repeatability. This means that the drive system can consistently and reliably return to the same position time after time, even after thousands of cycles. This level of repeatability is crucial in automated manufacturing processes, where consistency and reliability are key to ensuring high-quality output.

Another advantage of Mechanical Rolling Ring Linear Drive is its high load capacity. This drive system is capable of handling heavy loads with ease, making it suitable for a wide range of industrial applications. Whether it’s moving large components on a production line or lifting heavy materials in a warehouse, Mechanical Rolling Ring Linear Drive can handle the job with ease.

Furthermore, Mechanical Rolling Ring Linear Drive is known for its smooth and quiet operation. Unlike other types of linear drives that can be noisy and produce vibrations, this drive system operates quietly and smoothly, creating a more comfortable working environment for operators and reducing the risk of equipment wear and tear.

Additionally, Mechanical Rolling ring traverse drive is highly durable and reliable. This drive system is designed to withstand the rigors of industrial environments, including exposure to dust, dirt, and other contaminants. Its robust construction ensures that it can operate reliably for years with minimal maintenance, reducing downtime and increasing productivity.

Moreover, Mechanical Rolling Ring Linear Drive is easy to install and integrate into existing systems. Its modular design allows for easy customization and adaptation to specific application requirements, making it a versatile and flexible solution for a wide range of industrial automation needs.

In conclusion, Mechanical Rolling Ring Linear Drive offers a range of advantages that make it an ideal choice for industrial automation applications. From its high precision and accuracy to its excellent repeatability, high load capacity, smooth operation, durability, and ease of installation, this drive system provides a reliable and efficient solution for a variety of industrial automation challenges. Whether you’re looking to improve the performance of your manufacturing processes or enhance the efficiency of your warehouse operations, Mechanical Rolling Ring Linear Drive is a technology worth considering.

How to Properly Maintain and Troubleshoot Mechanical Rolling Ring Linear Drive Systems

Mechanical rolling ring linear drive systems are a crucial component in many industrial applications, providing precise linear motion for a variety of machinery. Proper maintenance and troubleshooting of these systems are essential to ensure optimal performance and longevity. In this article, we will discuss some key tips and techniques for maintaining and troubleshooting mechanical rolling ring linear drive systems.

Regular maintenance is key to keeping mechanical Rolling Ring Drives systems running smoothly. One of the most important maintenance tasks is lubrication. Proper lubrication helps reduce friction and wear on the moving parts of the system, extending its lifespan. It is important to use the correct type and amount of lubricant recommended by the manufacturer. Regularly inspecting the system for any signs of wear or damage is also crucial. Any worn or damaged components should be replaced promptly to prevent further damage to the system.

In addition to regular maintenance, troubleshooting mechanical rolling ring linear drive systems is essential to identify and address any issues that may arise. One common issue with these systems is misalignment. Misalignment can cause uneven wear on the rolling rings and lead to decreased performance. To troubleshoot misalignment, check the alignment of the drive shaft and make any necessary adjustments to ensure it is properly aligned with the rolling rings.

Another common issue with mechanical rolling ring linear drive systems is backlash. Backlash occurs when there is excessive play between the rolling rings and the drive shaft, resulting in inaccurate linear motion. To troubleshoot backlash, check for any loose or worn components in the system and tighten or replace them as needed. Adjusting the tension of the rolling rings can also help reduce backlash and improve the system’s performance.

In some cases, mechanical rolling ring linear drive systems may experience issues with overheating. Overheating can be caused by a variety of factors, including excessive friction, inadequate lubrication, or a malfunctioning cooling system. To troubleshoot overheating, check the system for any obstructions that may be blocking airflow and causing the system to overheat. Ensure that the cooling system is functioning properly and that the lubrication is adequate to reduce friction and heat buildup.

Properly maintaining and troubleshooting mechanical rolling ring linear drive systems requires a thorough understanding of the system’s components and operation. Regularly inspecting the system for signs of wear or damage, lubricating moving parts, and addressing any issues promptly are essential to keeping the system running smoothly. By following these tips and techniques, you can ensure that your mechanical rolling ring linear drive system performs optimally and lasts for years to come.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the optimal performance and longevity of mechanical rolling ring linear drive systems. By regularly inspecting the system, lubricating moving parts, and addressing any issues promptly, you can prevent costly downtime and repairs. With a thorough understanding of the system’s components and operation, you can effectively maintain and troubleshoot mechanical rolling ring linear drive systems to keep them running smoothly for years to come.