Table of Contents

Advantages of Using Rolling ring drive in Industrial Applications

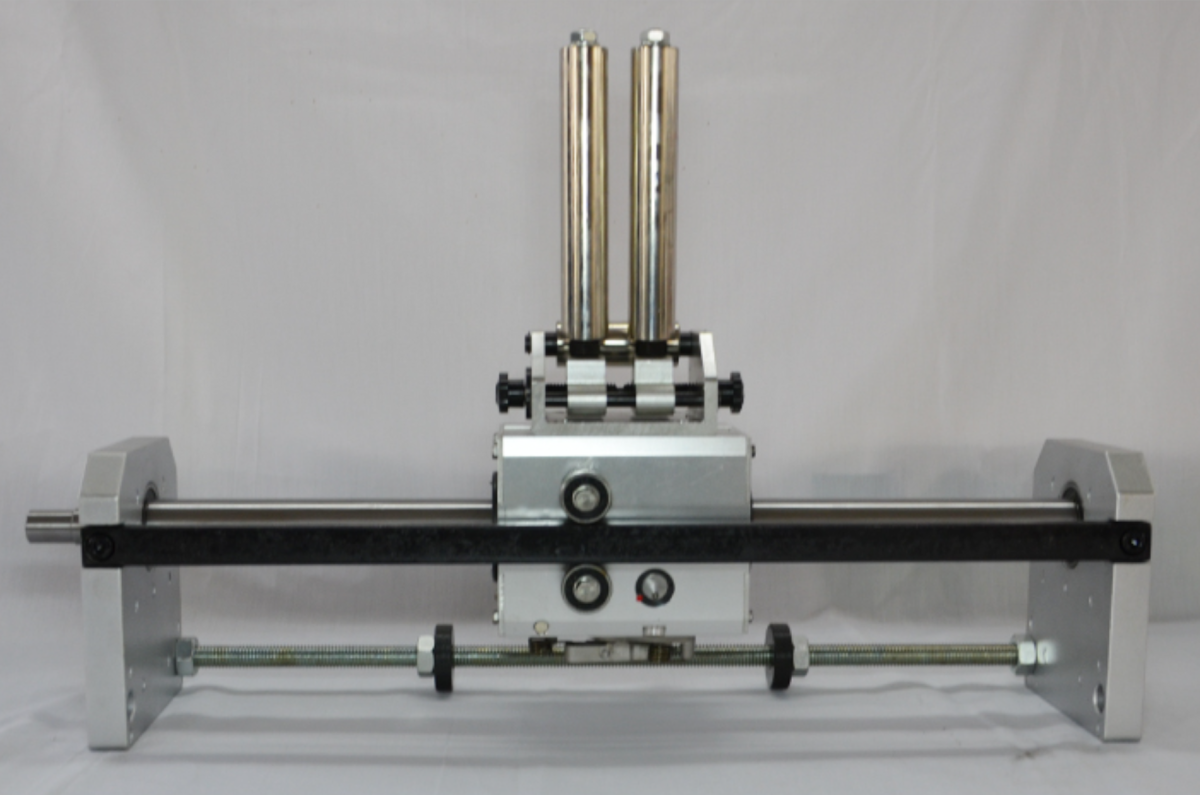

Rolling Ring Drives are a type of mechanical drive system that offers numerous advantages for industrial applications. These drives consist of a rolling ring that moves along a shaft, providing precise and reliable motion control. In this article, we will explore the benefits of using rolling ring drives in industrial settings.

One of the key advantages of rolling ring drives is their high level of precision. These drives are capable of delivering extremely accurate positioning, making them ideal for applications that require precise motion control. Whether it’s in a manufacturing plant or a robotic assembly line, rolling ring drives can ensure that movements are executed with precision and consistency.

In addition to precision, rolling ring drives also offer excellent repeatability. Once a motion profile is programmed into the drive system, it can be repeated over and over again with consistent results. This is crucial in industrial applications where the same motion needs to be performed repeatedly, such as in packaging lines or CNC machines. With rolling ring drives, manufacturers can rely on consistent performance and high-quality output.

Another advantage of rolling ring drives is their compact size. These drives are designed to be space-efficient, making them ideal for applications where space is limited. Whether it’s in a tight manufacturing environment or a small robotic arm, rolling ring drives can be easily integrated without taking up too much space. This compact design also makes them easy to install and maintain, saving time and resources for industrial operators.

Rolling ring drives are also known for their high efficiency. These drives are designed to minimize energy loss during operation, ensuring that power is used efficiently. This not only helps reduce energy costs for industrial operators but also contributes to a more sustainable and environmentally friendly operation. With rolling ring drives, manufacturers can achieve high levels of productivity while minimizing their carbon footprint.

Furthermore, rolling ring drives are highly versatile and can be customized to suit specific industrial applications. Whether it’s adjusting the speed, torque, or positioning accuracy, rolling ring drives can be tailored to meet the unique requirements of different industries. This flexibility makes them a popular choice for a wide range of applications, from automotive manufacturing to medical device production.

In conclusion, rolling ring drives offer a range of advantages for industrial applications. From their precision and repeatability to their compact size and high efficiency, these drives are a reliable and versatile solution for motion control in various industries. By choosing rolling ring drives, manufacturers can improve productivity, reduce costs, and achieve consistent and high-quality results in their operations.

How to Properly Maintain and Troubleshoot Rolling Ring Drive Systems

Rolling ring drives are a type of mechanical drive system that is commonly used in various industrial applications. These drives consist of a rolling ring that is driven by a rotating shaft, which in turn drives a linear motion component. Rolling ring drives are known for their simplicity, reliability, and high efficiency. However, like any mechanical system, rolling ring drives require proper maintenance and occasional troubleshooting to ensure optimal performance and longevity.

In addition to lubrication, it is important to regularly inspect the rolling ring drive system for any signs of wear or damage. This includes checking for loose or worn components, misalignment, and excessive vibration. Any issues should be addressed promptly to prevent further damage to the system. Regular maintenance checks can help identify potential problems before they escalate into more serious issues.

When troubleshooting a rolling ring drive system, it is important to start by identifying the root cause of the problem. This may involve checking for loose or worn components, misalignment, or improper lubrication. Once the cause of the issue has been identified, the appropriate corrective action can be taken. This may involve adjusting or replacing components, realigning the system, or reapplying lubricant.

In some cases, troubleshooting a rolling ring drive system may require the expertise of a trained technician. If you are unable to identify or resolve the issue on your own, it is important to seek professional help to prevent further damage to the system. A qualified technician will have the knowledge and experience to diagnose and repair the problem effectively.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the optimal performance and longevity of a rolling ring drive system. Regular lubrication, inspection, and timely repairs are key to keeping the system running smoothly and efficiently. By following the manufacturer’s recommendations and addressing any issues promptly, you can extend the life of your rolling ring drive system and avoid costly repairs down the line. If you encounter any problems that you are unable to resolve on your own, don’t hesitate to seek professional help. Remember, a well-maintained rolling ring drive system is a reliable and efficient drive system.