Table of Contents

Common Issues and Troubleshooting Tips for Take-up Machines used with Special Wire

Take-up machines are essential equipment in the wire and cable industry, used to wind wire onto spools or reels. When working with special wire, such as high-tensile or delicate wire, there are specific challenges that can arise during the winding process. In this article, we will discuss common issues that may occur when using take-up machines with special wire and provide troubleshooting tips to help you address these challenges effectively.

One common issue that can arise when using a Take-Up Machine with special wire is slippage. Slippage occurs when the wire does not wind tightly onto the spool, resulting in loose coils that can lead to tangling or breakage. This can be caused by a variety of factors, such as improper tension settings, worn-out drive belts, or a malfunctioning tension control system. To address this issue, check the tension settings on the machine and adjust them as needed. Replace any worn-out drive belts and ensure that the tension control system is functioning properly.

Another common issue that can occur when using a take-up machine with special wire is wire breakage. Special wire, such as high-tensile wire, can be more prone to breakage due to its unique properties. Wire breakage can be caused by excessive tension, sharp edges on the spool or guide rollers, or improper alignment of the wire during winding. To prevent wire breakage, ensure that the tension on the machine is set to the appropriate level for the wire being used. Check the spool and guide rollers for any sharp edges and smooth them out if necessary. Make sure that the wire is properly aligned during winding to reduce stress on the wire and minimize the risk of breakage.

In addition to slippage and wire breakage, another common issue that can occur when using a take-up machine with special wire is uneven winding. Uneven winding can result in coils that are not tightly packed, leading to inefficiencies in storage and transportation. This issue can be caused by uneven tension across the spool, misalignment of the wire during winding, or improper spooling techniques. To address uneven winding, check the tension settings on the machine and adjust them to ensure even tension across the spool. Make sure that the wire is properly aligned during winding to promote even distribution of the wire on the spool. Use proper spooling techniques, such as layer winding, to ensure that the wire is wound evenly and tightly onto the spool.

In conclusion, when using a take-up machine with special wire, it is important to be aware of the common issues that can arise and take proactive steps to address them. By monitoring tension settings, checking for sharp edges on spools and guide rollers, and ensuring proper alignment of the wire during winding, you can minimize the risk of slippage, wire breakage, and uneven winding. By following these troubleshooting tips, you can optimize the performance of your take-up machine and achieve efficient and reliable winding of special wire.

Advantages of Using a Take-up Machine for Special Wire

A take-up machine is a crucial piece of equipment in the wire manufacturing industry, especially when dealing with special wire. Special wire refers to wire that has unique properties or characteristics, such as high tensile strength, corrosion resistance, or specific electrical conductivity. These wires are often used in specialized applications where standard wire would not suffice. In this article, we will discuss the advantages of using a take-up machine for special wire.

One of the primary advantages of using a take-up machine for special wire is its ability to ensure consistent tension and winding quality. Special wire is often more delicate or sensitive than standard wire, and improper handling during the winding process can lead to defects or damage. A take-up machine is designed to carefully control the tension on the wire as it is wound onto a spool, ensuring that the wire is wound evenly and without any kinks or twists. This results in a higher-quality end product that meets the stringent requirements of specialized applications.

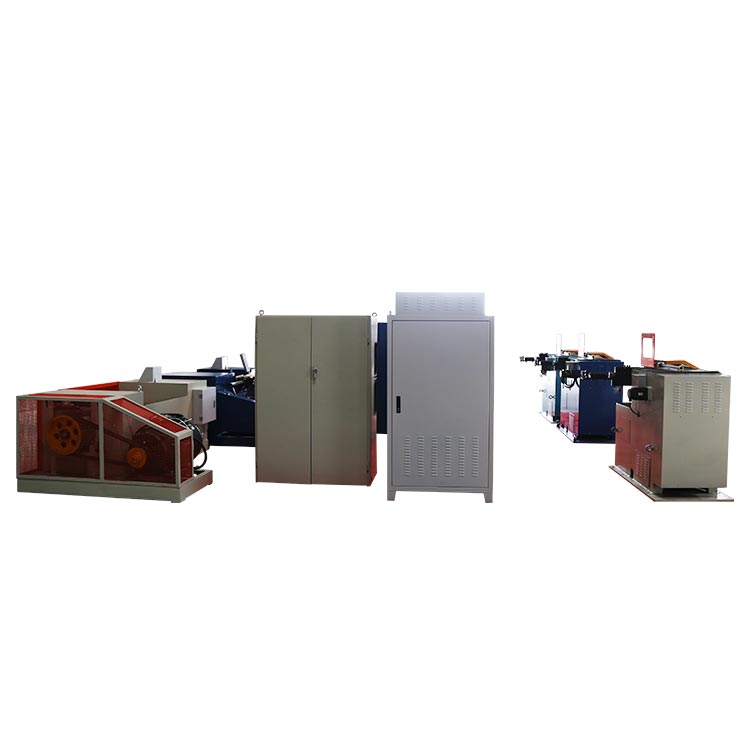

Additionally, a DS800 Take-Up Machine For Special Wire Winding can increase productivity and efficiency in the wire manufacturing process. Special wire is often produced in smaller quantities and with tighter tolerances than standard wire, making it more time-consuming and labor-intensive to handle. A take-up machine can automate the winding process, allowing operators to focus on other tasks while the machine takes care of winding the wire. This can lead to faster production times, reduced labor costs, and overall improved efficiency in the manufacturing process.

Furthermore, a take-up machine can help reduce waste and material loss during the winding process. Special wire is often more expensive than standard wire due to its unique properties or composition. Any defects or damage that occur during the winding process can result in significant material loss and increased production costs. A take-up machine can minimize the risk of defects by ensuring that the wire is wound properly and without any issues. This can help manufacturers save money on material costs and improve their overall profitability.

Another advantage of using a take-up machine for special wire is its versatility and adaptability. Special wire comes in a variety of sizes, shapes, and materials, each requiring specific handling and winding techniques. A take-up machine can be customized to accommodate different types of special wire, allowing manufacturers to produce a wide range of products without the need for multiple machines. This flexibility can help manufacturers streamline their production processes and respond quickly to changing market demands.

In conclusion, the advantages of using a take-up machine for special wire are numerous and significant. From ensuring consistent winding quality to increasing productivity and efficiency, a take-up machine is an essential tool for manufacturers working with special wire. By investing in a high-quality take-up machine, manufacturers can improve the quality of their products, reduce waste and material loss, and enhance their overall competitiveness in the market.

How to Properly Maintain and Care for a Take-up Machine for Special Wire

A take-up machine for special wire is an essential piece of equipment in various industries that rely on the production and processing of wire products. These machines are designed to wind wire onto a spool or reel, ensuring that it is properly stored and ready for use in the manufacturing process. Proper maintenance and care of a take-up machine are crucial to ensure its longevity and efficiency. In this article, we will discuss some important tips on how to properly maintain and care for a take-up machine for special wire.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, bearings, and gears, and replace them as needed. Lubricate moving parts to prevent friction and ensure smooth operation. Regular maintenance checks can help prevent costly repairs and downtime in the future.

In addition to regular inspections, it is important to clean the machine regularly to remove any dirt, dust, or debris that may accumulate over time. Use a soft brush or cloth to gently clean the machine, being careful not to damage any delicate components. Keeping the machine clean can help prevent malfunctions and ensure optimal performance.

Another important aspect of maintaining a take-up machine for special wire is to properly adjust the tension settings. The tension of the wire must be carefully controlled to ensure that it is wound onto the spool or reel evenly and securely. Improper tension settings can lead to uneven winding, which can affect the quality of the wire and cause issues during the manufacturing process. Regularly check and adjust the tension settings as needed to ensure consistent and reliable performance.

It is also important to regularly calibrate the machine to ensure accurate winding of the wire. Calibrating the machine involves adjusting the speed, tension, and other settings to ensure that the wire is wound onto the spool or reel correctly. Improper calibration can lead to issues such as overwinding or underwinding, which can affect the quality of the wire and cause production delays. Regularly calibrating the machine can help ensure consistent and accurate winding of the wire.

In addition to regular maintenance and care, it is important to follow the manufacturer’s guidelines for operating the machine. This includes using the machine only for its intended purpose, following proper safety procedures, and avoiding overloading the machine. Operating the machine correctly can help prevent damage and ensure its longevity.

In conclusion, proper maintenance and care of a take-up machine for special wire are essential to ensure its longevity and efficiency. Regular inspections, cleaning, adjusting tension settings, calibrating the machine, and following manufacturer’s guidelines are all important aspects of maintaining a take-up machine. By following these tips, you can help ensure that your machine operates smoothly and reliably, allowing you to produce high-quality wire products efficiently.