Table of Contents

Understand The Advantages of Smooth Shaft Traverse Drive in Industrial Applications

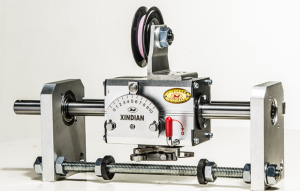

Smooth Shaft Traverse Unit systems are a crucial component in various industrial applications, providing precise and efficient movement of materials along a linear path. These systems offer several advantages that make them a popular choice for industries such as manufacturing, packaging, and material handling.

One of the key advantages of smooth shaft traverse drives is their high level of precision. These systems are designed to move materials with accuracy and consistency, ensuring that products are positioned correctly and that production processes run smoothly. This precision is essential in industries where even the slightest deviation can result in costly errors or defects.

In addition to precision, smooth shaft traverse drives also offer excellent speed control. These systems can be easily adjusted to accommodate different production speeds, allowing for increased flexibility and efficiency in manufacturing processes. Whether a slow, steady pace is required for delicate materials or a rapid pace is needed for high-volume production, smooth shaft traverse drives can easily meet the demands of various applications.

Another advantage of Rolling Ring Traverse Unit is their durability and reliability. These systems are built to withstand the rigors of industrial environments, with robust construction and high-quality components that ensure long-lasting performance. This reliability is essential for minimizing downtime and maximizing productivity, making smooth shaft traverse drives a cost-effective solution for industrial applications.

Smooth shaft traverse drives are also known for their smooth and quiet operation. These systems are designed to minimize noise and vibration, creating a more comfortable working environment for operators and reducing the risk of equipment damage. This quiet operation is particularly beneficial in industries where noise levels must be kept to a minimum, such as in cleanroom environments or facilities located in residential areas.

Furthermore, smooth shaft traverse drives are easy to install and maintain, making them a convenient choice for industrial applications. These systems can be quickly integrated into existing production lines, minimizing disruption to operations and allowing for seamless implementation. Additionally, routine maintenance tasks are straightforward and can be easily performed by trained personnel, reducing the need for costly repairs or downtime.

Overall, smooth shaft traverse drives offer a range of advantages that make them an ideal choice for industrial applications. From their precision and speed control to their durability and reliability, these systems provide a cost-effective solution for moving materials along a linear path. With their smooth and quiet operation, easy installation, and low maintenance requirements, smooth shaft traverse drives are a valuable asset for industries looking to optimize their production processes and improve overall efficiency.

How to Maintain and Troubleshoot Smooth Shaft Traverse Drive Systems

Roll ring traverse drive systems are essential components in various industrial applications, providing precise control over the movement of materials along a linear path. These systems are commonly used in industries such as textiles, paper manufacturing, and packaging, where accurate and consistent material handling is crucial for efficient production processes. To ensure the smooth operation of smooth shaft traverse drive systems, regular maintenance and troubleshooting are necessary.

One of the key maintenance tasks for smooth shaft traverse drive systems is lubrication. Proper lubrication helps reduce friction between moving parts, preventing wear and tear that can lead to system malfunctions. It is important to use the correct type of lubricant recommended by the manufacturer and to apply it at regular intervals to ensure optimal performance. Additionally, it is essential to clean the drive system regularly to remove any dirt or debris that may accumulate and interfere with its operation.

Another important aspect of maintaining Rolling ring traverse drive systems is checking for any signs of wear or damage. Inspecting the drive system for loose or worn components, such as belts, pulleys, or bearings, can help prevent potential breakdowns and costly repairs. It is also advisable to check the alignment of the drive system to ensure that all components are properly positioned and functioning as intended.

In the event of a malfunction or breakdown, troubleshooting smooth shaft traverse drive systems requires a systematic approach to identify and resolve the issue. One common problem that may occur is belt slippage, which can result in erratic or uneven movement of materials along the linear path. To address this issue, it is important to check the tension of the belts and adjust them as needed to ensure proper alignment and grip.

Another potential issue with smooth shaft traverse drive systems is motor overheating, which can be caused by excessive friction or overloading. In such cases, it is important to check the motor for any signs of overheating, such as unusual noises or a burning smell, and to address the root cause of the problem promptly. This may involve reducing the load on the motor, improving ventilation around the motor, or replacing worn components that may be causing excessive friction.

In conclusion, maintaining and troubleshooting smooth shaft traverse drive systems is essential for ensuring their reliable operation and longevity. By following a regular maintenance schedule, including lubrication, cleaning, and inspection of components, and addressing any issues promptly, operators can prevent costly breakdowns and downtime. In the event of a malfunction, a systematic approach to troubleshooting can help identify and resolve the issue efficiently, minimizing disruption to production processes. Overall, proper maintenance and troubleshooting practices are key to maximizing the performance and lifespan of smooth shaft traverse drive systems in industrial applications.