Table of Contents

Tips for Choosing the Right Take-Up Machine For Special Wire Winding

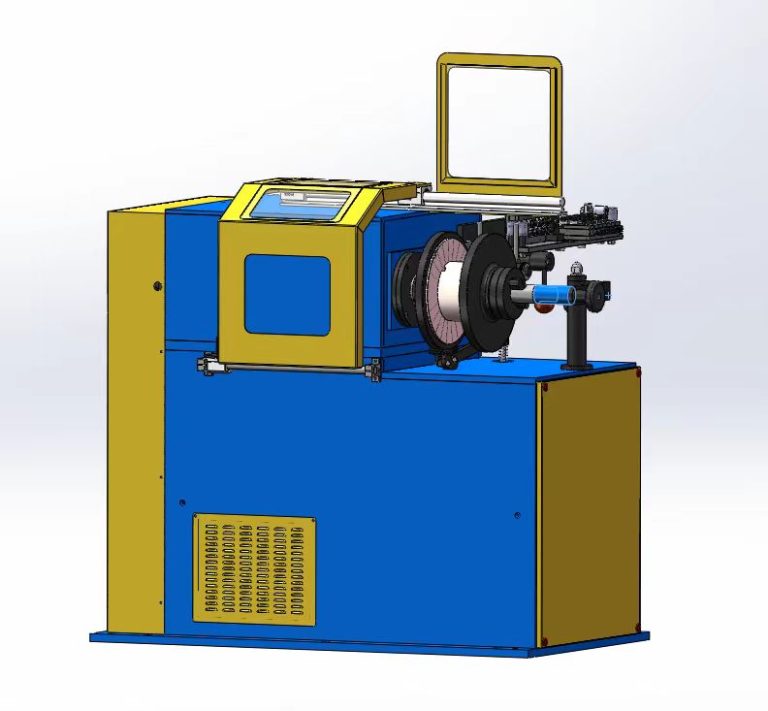

When it comes to special wire winding, having the right take-up machine is crucial for ensuring a smooth and efficient process. Take-up machines are used to wind wire onto a spool or reel, and they come in a variety of sizes and configurations to accommodate different types of wire and winding requirements. In this article, we will discuss some tips for choosing the right DS800 Take-Up Machine For Special Wire Winding applications.

One of the first things to consider when selecting a take-up machine is the type of wire you will be winding. Different types of wire have different properties, such as thickness, flexibility, and tensile strength, which can affect the performance of the take-up machine. For example, if you are winding thin, delicate wire, you will need a machine with precise tension control to prevent breakage. On the other hand, if you are winding thick, rigid wire, you will need a machine with a powerful motor to handle the increased tension.

Another important factor to consider is the speed and capacity of the take-up machine. The speed at which the machine can wind the wire onto the spool will determine how quickly you can complete your winding process. Additionally, the capacity of the machine will determine how much wire you can wind at once. If you have a high-volume production process, you will need a machine with a large capacity and fast winding speed to keep up with demand.

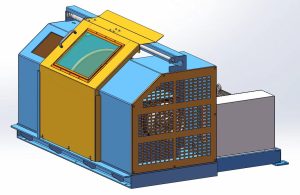

It is also important to consider the size and layout of your workspace when choosing a take-up machine. Some machines are compact and can be easily integrated into existing production lines, while others are larger and require more space. Additionally, some machines are designed for vertical winding, while others are designed for horizontal winding. Consider the layout of your workspace and the flow of your production process to determine the best configuration for your take-up machine.

When selecting a take-up machine, it is also important to consider the level of automation and control features that are available. Some machines come with advanced features such as programmable tension control, automatic spool changeover, and remote monitoring capabilities. These features can help improve the efficiency and accuracy of your wire winding process. However, they may also come with a higher price tag, so it is important to weigh the benefits against the cost.

Finally, it is important to consider the reputation and reliability of the manufacturer when choosing a take-up machine. Look for a manufacturer with a proven track record of producing high-quality machines that are built to last. Read customer reviews and testimonials to get an idea of the level of customer satisfaction with the manufacturer’s products and services.

In conclusion, choosing the right take-up machine for special wire winding applications requires careful consideration of the type of wire, speed and capacity requirements, workspace layout, automation features, and manufacturer reputation. By taking the time to research and evaluate your options, you can ensure that you select a machine that meets your specific needs and helps you achieve optimal results in your wire winding process.

Advantages of Using a Take-up Machine for Special Wire Winding

Special wire winding is a process that requires precision and accuracy to ensure the quality of the final product. One of the key components in this process is the take-up machine, which plays a crucial role in winding the wire onto a spool or bobbin. There are several advantages to using a take-up machine for special wire winding, which we will explore in this article.

First and foremost, a take-up machine helps to ensure consistent tension and winding speed during the wire winding process. This is essential for achieving uniformity in the winding pattern and preventing any irregularities or defects in the final product. By maintaining a constant tension and speed, the take-up machine helps to produce high-quality wire coils that meet the required specifications.

In addition to ensuring consistent tension and speed, a take-up machine also helps to improve the efficiency of the wire winding process. Manual winding can be time-consuming and labor-intensive, especially when dealing with large quantities of wire. By automating the winding process with a take-up machine, manufacturers can significantly increase their production output and reduce the time and labor required for winding.

Furthermore, a take-up machine offers greater control and flexibility in the wire winding process. With adjustable settings for tension, speed, and winding direction, operators can easily customize the machine to meet the specific requirements of each wire winding job. This level of control allows for greater precision and accuracy in the winding process, resulting in higher quality wire coils.

Another advantage of using a take-up machine for special wire winding is the ability to handle a wide range of wire sizes and materials. Whether working with thin gauge wires or thick cables, the machine can be easily adjusted to accommodate different wire diameters and materials. This versatility makes the take-up machine suitable for a variety of applications in industries such as electronics, telecommunications, and automotive.

Additionally, a take-up machine helps to reduce the risk of errors and defects in the wire winding process. Manual winding can be prone to human error, leading to inconsistencies in the winding pattern and potential defects in the final product. By automating the process with a take-up machine, manufacturers can minimize the risk of errors and ensure a higher level of quality control in their wire winding operations.

Overall, the advantages of using a take-up machine for special wire winding are clear. From ensuring consistent tension and speed to improving efficiency and control, the machine offers numerous benefits for manufacturers looking to produce high-quality wire coils. By investing in a take-up machine, manufacturers can streamline their wire winding process, increase production output, and achieve superior results in their wire winding operations.