Table of Contents

Advanteges Of Using Semi-Auto Respooling Machine For Cable Manufacturing

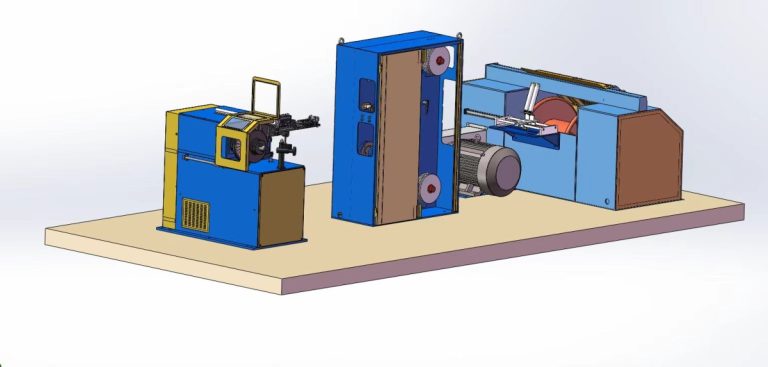

In The World Of Cable Manufacturing, Efficiency And Precision Are Key Factors In Ensuring High-Quality Products Are Produced In A Timely Manner. One Tool That Has Revolutionized The Industry Is The Semi-Auto Respooling Machine. This Innovative Piece Of Equipment Offers A Wide Range Of Benefits That Can Greatly Improve The Manufacturing Process.

One Of The Primary Advantages Of Using A Semi-Auto Respooling Machine Is Its Ability To Increase Productivity. By Automating The Respooling Process, Workers Can Save Valuable Time And Energy That Would Otherwise Be Spent Manually Respooling Cables. This Allows For Faster Production Times And Ultimately Leads To Higher Output Levels.

Additionally, The Semi-Auto Respooling Machine Offers A High Level Of Accuracy And Consistency. With Precise Measurements And Controlled Tension Settings, This Machine Ensures That Each Cable Is Respooled With The Same Level Of Quality Every Time. This Consistency Is Crucial In Maintaining The Integrity Of The Cables And Reducing The Risk Of Defects Or Errors In The Final Product.

Another Benefit Of Using A Semi-Auto Respooling Machine Is Its Versatility. These Machines Are Designed To Accommodate A Wide Range Of Cable Sizes And Types, Making Them Suitable For A Variety Of Manufacturing Needs. Whether You Are Working With Small, Delicate Cables Or Large, Heavy-Duty Ones, A Semi-Auto Respooling Machine Can Handle The Job With Ease.

Furthermore, The Semi-Auto Respooling Machine Is User-Friendly And Easy To Operate. With Intuitive Controls And A Simple Interface, Workers Can Quickly Learn How To Use The Machine Effectively. This Reduces The Need For Extensive Training And Allows For Seamless Integration Into The Manufacturing Process.

In Addition To Improving Productivity And Accuracy, The Semi-Auto Respooling Machine Also Offers Cost-Saving Benefits. By Reducing The Need For Manual Labor And Minimizing The Risk Of Errors, This Machine Can Help Lower Production Costs And Increase Overall Profitability. In The Long Run, Investing In A Semi-Auto Respooling Machine Can Lead To Significant Savings For Cable Manufacturers.

Overall, The Benefits Of Using A Semi-Auto Respooling Machine For Cable Manufacturing Are Clear. From Increased Productivity And Accuracy To Versatility And Cost Savings, This Innovative Piece Of Equipment Offers A Wide Range Of Advantages That Can Greatly Improve The Manufacturing Process. By Incorporating A Semi-Auto Respooling Machine Into Your Operations, You Can Streamline Production, Enhance Quality, And Ultimately Achieve Greater Success In The Competitive Cable Manufacturing Industry.

How To Choose The Right Semi-Auto Respooling Machine For Your Business

In Today’s Fast-Paced World, Businesses Are Constantly Looking For Ways To Improve Efficiency And Productivity. One Way To Achieve This Is By Investing In The Right Equipment, Such As A Semi-Auto Respooling Machine. These Machines Are Designed To Quickly And Accurately Respool Various Types Of Materials, Such As Wire, Cable, And Tubing. However, With So Many Options Available On The Market, It Can Be Challenging To Choose The Right One For Your Business.

When Selecting A Semi-Auto Respooling Machine, There Are Several Factors To Consider. One Of The Most Important Things To Think About Is The Type Of Material You Will Be Respooling. Different Machines Are Designed To Handle Different Materials, So It’s Essential To Choose One That Is Compatible With The Material You Work With. For Example, If You Primarily Respool Wire, You Will Need A Machine That Is Specifically Designed For Wire Respooling.

Another Crucial Factor To Consider Is The Speed And Capacity Of The Machine. Depending On The Volume Of Material You Need To Respool, You May Require A Machine That Can Handle A High Throughput. Look For A Machine That Offers Adjustable Speed Settings So You Can Customize The Respooling Process To Meet Your Specific Needs. Additionally, Consider The Size Of The Spools You Will Be Using And Make Sure The Machine Can Accommodate Them.

It’s Also Essential To Consider The Level Of Automation You Require. Semi-Auto Respooling Machines Come In Various Levels Of Automation, From Basic Manual Machines To Fully Automated Systems. If You Have A Small Operation And Don’t Mind Some Manual Labor, A Basic Machine May Be Sufficient. However, If You Have A High-Volume Operation And Need To Maximize Efficiency, A Fully Automated System May Be The Best Choice.

When Choosing A Semi-Auto Respooling Machine, It’s Crucial To Consider The Overall Quality And Reliability Of The Machine. Look For A Reputable Manufacturer With A Track Record Of Producing High-Quality Equipment. Read Reviews And Testimonials From Other Businesses That Have Used The Machine To Get An Idea Of Its Performance And Reliability. Additionally, Consider The Warranty And After-Sales Support Offered By The Manufacturer To Ensure You Can Get Help If Any Issues Arise.

Cost Is Another Important Factor To Consider When Choosing A Semi-Auto Respooling Machine. While It’s Essential To Stay Within Your Budget, It’s Also Crucial To Consider The Long-Term Value Of The Machine. A Higher-Quality Machine May Cost More Upfront But Could Save You Money In The Long Run By Reducing Downtime And Maintenance Costs. Consider The Return On Investment Of The Machine And Choose One That Offers The Best Value For Your Business.

In Conclusion, Choosing The Right Semi-Auto Respooling Machine For Your Business Is A Crucial Decision That Can Have A Significant Impact On Your Productivity And Efficiency. Consider Factors Such As The Type Of Material You Will Be Respooling, The Speed And Capacity Of The Machine, The Level Of Automation Required, The Quality And Reliability Of The Machine, And The Cost. By Carefully Evaluating These Factors And Choosing A Machine That Meets Your Specific Needs, You Can Ensure That You Make A Wise Investment That Will Benefit Your Business For Years To Come.