Table of Contents

Exploring The Benefits of Using precision wire Layer Winding Machine in Industrial Applications

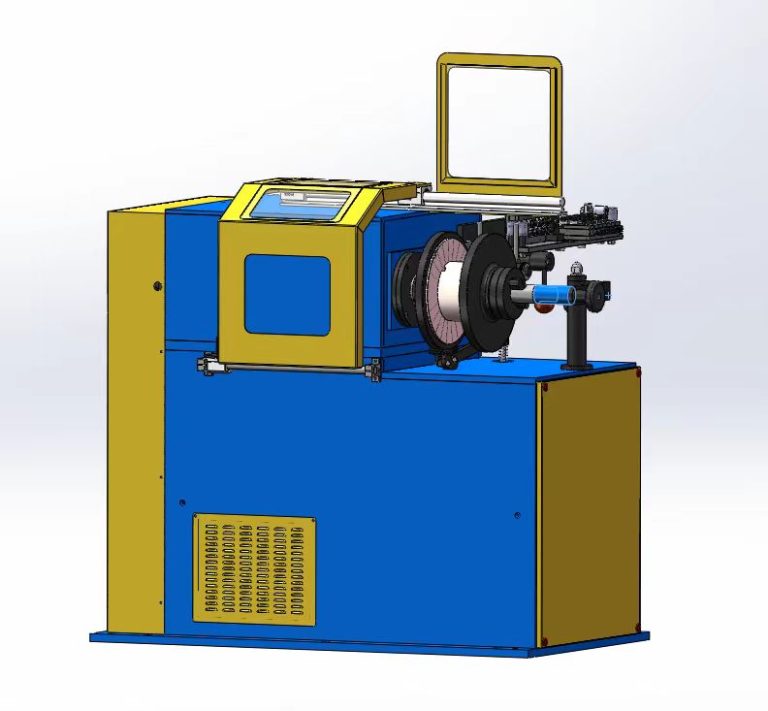

Precision wire layer winding machines are essential tools in various industrial applications where precise and accurate winding of wire is required. These machines offer a wide range of benefits that make them indispensable in industries such as electronics, automotive, aerospace, and telecommunications. In this article, we will explore the advantages of using a precision wire layer winding machine in industrial applications.

One of the key benefits of using a precision wire layer winding machine is the ability to achieve consistent and uniform winding of wire. These machines are equipped with advanced technology that ensures each layer of wire is wound with precision and accuracy. This is crucial in industries where the quality of the final product is dependent on the uniformity of the wire winding.

Furthermore, Flat Wire Precision Layer Winding Machine are capable of handling a wide range of wire sizes and types. This versatility allows industries to use the same machine for different applications, saving time and money on equipment costs. Whether you are working with thin gauge wire or thick gauge wire, a precision wire layer winding machine can accommodate your needs.

In addition to their versatility, precision wire layer winding machines are also highly efficient. These machines are designed to operate at high speeds, allowing for faster production times and increased output. This is especially beneficial in industries where time is of the essence and meeting deadlines is crucial.

Another advantage of using a precision wire layer winding machine is the reduction of waste. These machines are programmed to minimize the amount of wire used during the winding process, resulting in less material waste and cost savings for the industry. This is particularly important in industries where raw materials are expensive and every bit of material counts.

Moreover, precision wire layer winding machines are equipped with safety features that protect operators from potential hazards. These machines are designed to operate smoothly and efficiently, reducing the risk of accidents and injuries in the workplace. This not only ensures the safety of workers but also increases productivity by minimizing downtime due to accidents.

Furthermore, precision wire layer winding machines are easy to operate and maintain. These machines are equipped with user-friendly interfaces that allow operators to program and control the winding process with ease. Additionally, maintenance requirements are minimal, reducing downtime and increasing overall efficiency in the workplace.

In conclusion, the benefits of using a precision wire layer winding machine in industrial applications are numerous. From achieving consistent and uniform winding of wire to increasing efficiency and reducing waste, these machines play a crucial role in various industries. With their versatility, efficiency, safety features, and ease of operation, precision wire layer winding machines are essential tools for any industry that requires precise and accurate wire winding.

How to Choose the Right Precision Wire Layer Winding Machine for Your Specific Needs

When it comes to choosing the right Flat Cable Precision Layer Winding Machine for your specific needs, there are several factors to consider. These machines are essential for winding wire onto spools or bobbins with precision and accuracy. Whether you are in the electronics, automotive, or aerospace industry, having the right winding machine can make a significant difference in the quality and efficiency of your production process.

One of the first things to consider when choosing a precision wire layer winding machine is the type of wire you will be working with. Different machines are designed to handle different types of wire, such as copper, aluminum, or even specialty wires like magnet wire. It is essential to choose a machine that is compatible with the type and gauge of wire you will be using to ensure optimal performance.

Another important factor to consider is the speed and capacity of the winding machine. Depending on the volume of wire you need to wind and the production deadlines you have to meet, you will need to choose a machine that can handle the workload efficiently. Some machines are designed for high-speed winding, while others are better suited for smaller-scale operations. Consider your production requirements and choose a machine that can meet your needs without compromising on quality.

In addition to speed and capacity, it is also crucial to consider the precision and accuracy of the winding machine. The whole point of using a precision wire layer winding machine is to ensure that the wire is wound onto the spool or bobbin with consistent tension and alignment. Look for machines that offer features like tension control, programmable winding patterns, and automatic stop functions to ensure that your wire winding is precise and error-free.

Furthermore, consider the overall durability and reliability of the winding machine. You want a machine that can withstand the rigors of daily use and continue to perform consistently over time. Look for machines made from high-quality materials and with a reputation for reliability. It is also a good idea to choose a machine from a reputable manufacturer with a track record of producing reliable and durable equipment.

When choosing a precision wire layer winding machine, it is also essential to consider the ease of use and maintenance. Look for machines that are user-friendly and come with clear instructions for operation and maintenance. Consider whether the machine requires any specialized training or tools to operate and maintain. Choosing a machine that is easy to use and maintain can save you time and money in the long run.

In conclusion, choosing the right precision wire layer winding machine for your specific needs requires careful consideration of several factors. From the type of wire you will be working with to the speed, capacity, precision, durability, and ease of use of the machine, there are many factors to consider. By taking the time to research and evaluate your options, you can choose a machine that will meet your production requirements and help you achieve optimal results.