Table of Contents

Advantages of Using Rolling Ring Linear Traverse Units in Industrial Automation

Rolling ring traverse drive are a crucial component in industrial automation systems. These units provide precise linear motion, making them ideal for a wide range of applications in industries such as manufacturing, packaging, and material handling. In this article, we will explore the advantages of using rolling ring linear traverse units in industrial automation.

One of the key advantages of rolling ring linear traverse units is their high level of precision. These units are designed to provide smooth and accurate linear motion, ensuring that the positioning of components or products is always precise. This level of precision is essential in industrial automation, where even the smallest deviation can lead to costly errors or inefficiencies.

Another advantage of Rolling ring linear drive is their versatility. These units can be easily integrated into existing automation systems, making them a flexible and cost-effective solution for a wide range of applications. Whether you need to move products along a conveyor belt, position components for assembly, or perform any other linear motion task, rolling ring linear traverse units can be customized to meet your specific requirements.

In addition to their precision and versatility, rolling ring linear traverse units are also known for their durability and reliability. These units are built to withstand the rigors of industrial environments, ensuring that they can continue to operate smoothly and efficiently even in the most demanding conditions. This reliability is essential in industrial automation, where downtime can have a significant impact on productivity and profitability.

Furthermore, rolling ring linear traverse units are easy to maintain and operate. With simple installation and minimal maintenance requirements, these units can help to reduce downtime and increase overall efficiency in industrial automation systems. This ease of use makes rolling ring linear traverse units a popular choice for manufacturers looking to streamline their operations and improve productivity.

Another advantage of using rolling ring linear traverse units in industrial automation is their cost-effectiveness. These units offer a high level of performance at a relatively low cost, making them an attractive option for businesses looking to maximize their return on investment. By improving efficiency, reducing downtime, and increasing productivity, rolling ring linear traverse units can help to lower operating costs and improve overall profitability.

In conclusion, rolling ring linear traverse units offer a wide range of advantages for industrial automation applications. From their precision and versatility to their durability and reliability, these units are an essential component in modern automation systems. By choosing rolling ring linear traverse units for your automation needs, you can improve efficiency, reduce costs, and increase productivity in your operations.

How to Select the Right Rolling Ring Linear Traverse Unit for Your Application

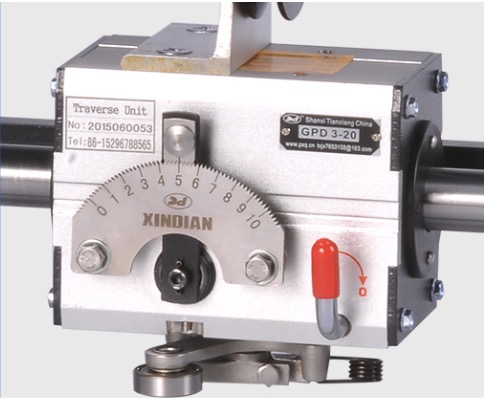

Rolling ring linear traverse units are a type of linear motion system that is commonly used in various industrial applications. These units are designed to provide smooth and precise linear motion, making them ideal for applications that require high accuracy and repeatability. When selecting a Smooth Shaft Traverse Unit for your application, there are several factors that you need to consider to ensure that you choose the right unit for your specific needs.

One of the most important factors to consider when selecting a rolling ring linear traverse unit is the load capacity of the unit. The load capacity of a unit is the maximum amount of weight that the unit can support while still maintaining its performance and accuracy. It is important to choose a unit with a load capacity that is sufficient for the weight of the load that will be placed on the unit. Choosing a unit with a load capacity that is too low can result in poor performance and premature failure of the unit.

Another important factor to consider when selecting a rolling ring linear traverse unit is the speed and acceleration requirements of your application. Different units are designed to operate at different speeds and accelerations, so it is important to choose a unit that can meet the speed and acceleration requirements of your specific application. Choosing a unit that is not capable of operating at the required speed and acceleration can result in poor performance and reduced efficiency of your application.

In addition to load capacity and speed requirements, it is also important to consider the stroke length of the rolling ring linear traverse unit. The stroke length is the maximum distance that the unit can travel in a single motion. It is important to choose a unit with a stroke length that is sufficient for the distance that the unit needs to travel in your application. Choosing a unit with a stroke length that is too short can result in limited motion and reduced functionality of your application.

When selecting a rolling ring linear traverse unit, it is also important to consider the accuracy and repeatability requirements of your application. Different units are designed to provide different levels of accuracy and repeatability, so it is important to choose a unit that can meet the precision requirements of your specific application. Choosing a unit that is not accurate or repeatable enough can result in poor performance and reduced quality of your application.

Finally, it is important to consider the environmental conditions in which the rolling ring linear traverse unit will be operating. Some units are designed to operate in harsh environments, such as high temperatures or corrosive atmospheres, while others are designed for more controlled environments. It is important to choose a unit that is suitable for the environmental conditions in which it will be operating to ensure that it will perform reliably and efficiently.

In conclusion, selecting the right rolling ring linear traverse unit for your application requires careful consideration of several factors, including load capacity, speed and acceleration requirements, stroke length, accuracy and repeatability requirements, and environmental conditions. By taking these factors into account, you can ensure that you choose a unit that will meet the specific needs of your application and provide reliable and efficient performance.