How To Properly Maintain And Troubleshoot Mechanical Rolling ring linear drive Systems

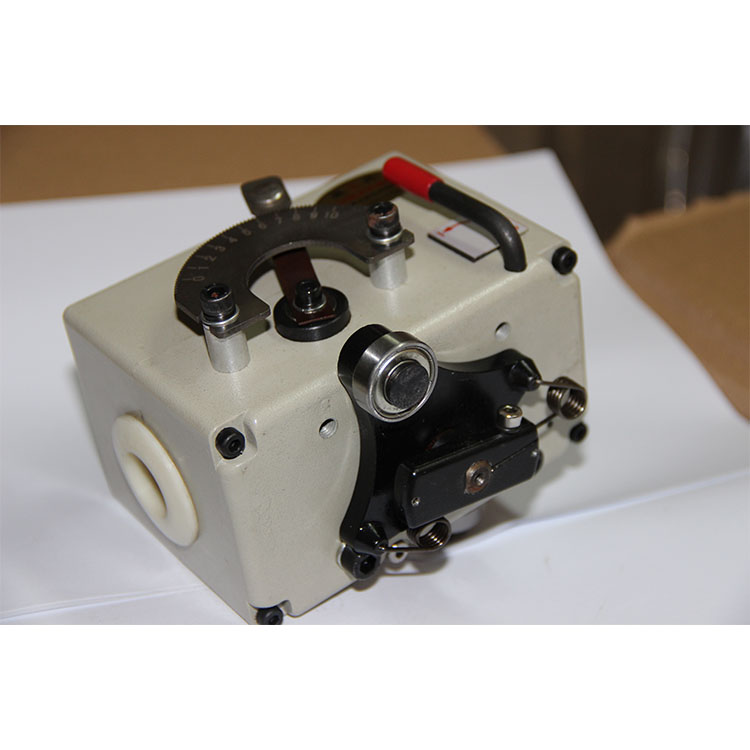

Mechanical Rolling Ring Linear Drive Systems Are A Crucial Component In Many Industrial Applications, Providing Precise Linear Motion For A Variety Of Machinery. Proper Maintenance And Troubleshooting Of These Systems Are Essential To Ensure Optimal Performance And Longevity. In This Article, We Will Discuss Some Key Tips And Techniques For Maintaining And Troubleshooting Mechanical Smooth Shaft Traverse Unit Systems.

Regular Maintenance Is Key To Keeping Mechanical Rolling Ring Linear Drive Systems Running Smoothly. One Of The Most Important Maintenance Tasks Is Lubrication. Proper Lubrication Helps Reduce Friction And Wear On The Moving Parts Of The System, Extending Its Lifespan. It Is Important To Use The Correct Type And Amount Of Lubricant Recommended By The Manufacturer. Regularly Inspecting The System For Any Signs Of Wear Or Damage Is Also Crucial. Any Worn Or Damaged Components Should Be Replaced Promptly To Prevent Further Damage To The System.

In Addition To Regular Maintenance, Troubleshooting Mechanical Rolling Ring Driver Systems Is Essential To Identify And Address Any Issues That May Arise. One Common Issue With These Systems Is Misalignment. Misalignment Can Cause Uneven Wear On The Rolling Rings And Lead To Decreased Performance. To Troubleshoot Misalignment, Check The Alignment Of The Drive Shaft And Make Any Necessary Adjustments To Ensure It Is Properly Aligned With The Rolling Rings.

Another Common Issue With Mechanical Rolling Ring Linear Drive Systems Is Backlash. Backlash Occurs When There Is Excessive Play Between The Rolling Rings And The Drive Shaft, Resulting In Inaccurate Linear Motion. To Troubleshoot Backlash, Check For Any Loose Or Worn Components In The System And Tighten Or Replace Them As Needed. Adjusting The Tension Of The Rolling Rings Can Also Help Reduce Backlash And Improve The System’s Performance.

In Some Cases, Mechanical Rolling Ring Linear Drive Systems May Experience Issues With Overheating. Overheating Can Be Caused By A Variety Of Factors, Including Excessive Friction, Inadequate Lubrication, Or A Malfunctioning Cooling System. To Troubleshoot Overheating, Check The System For Any Obstructions That May Be Blocking Airflow And Causing The System To Overheat. Ensure That The Cooling System Is Functioning Properly And That The Lubrication Is Adequate To Reduce Friction And Heat Buildup.

Properly Maintaining And Troubleshooting Mechanical Rolling Ring Linear Drive Systems Requires A Thorough Understanding Of The System’s Components And Operation. Regularly Inspecting The System For Signs Of Wear Or Damage, Lubricating Moving Parts, And Addressing Any Issues Promptly Are Essential To Keeping The System Running Smoothly. By Following These Tips And Techniques, You Can Ensure That Your Mechanical Rolling Ring Linear Drive System Performs Optimally And Lasts For Years To Come.

In Conclusion, Proper Maintenance And Troubleshooting Are Essential For Ensuring The Optimal Performance And Longevity Of Mechanical Rolling Ring Linear Drive Systems. By Regularly Inspecting The System, Lubricating Moving Parts, And Addressing Any Issues Promptly, You Can Prevent Costly Downtime And Repairs. With A Thorough Understanding Of The System’s Components And Operation, You Can Effectively Maintain And Troubleshoot Mechanical Rolling Ring Linear Drive Systems To Keep Them Running Smoothly For Years To Come.