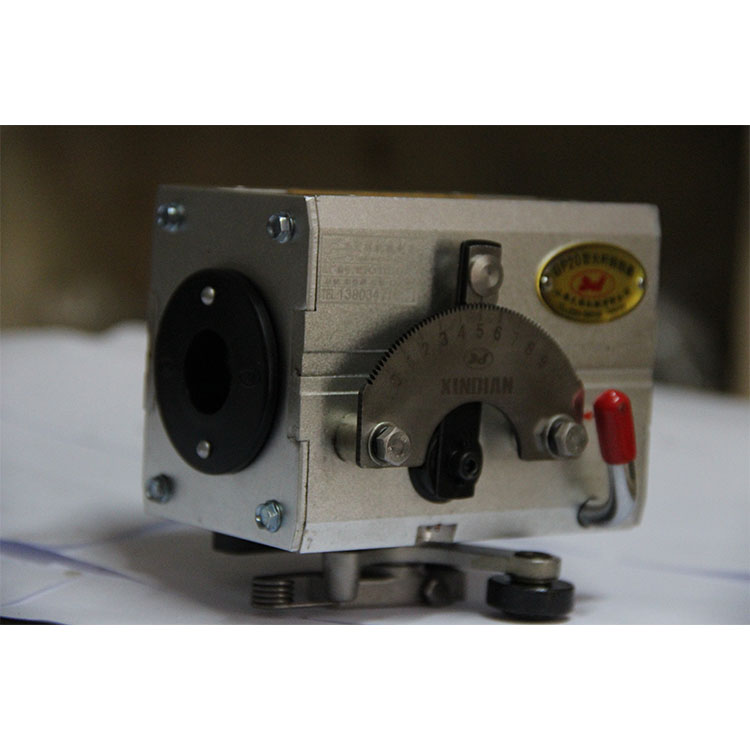

How To Properly Maintain And Troubleshoot Roll Ring Traverse Unit In Manufacturing Processes

Roll Ring Traverse Units Are Essential Components In Manufacturing Processes That Involve Winding, Spooling, Or Traversing Materials Such As Wire, Cable, Or Textiles. These Units Play A Crucial Role In Ensuring The Smooth And Efficient Operation Of The Production Line. However, Like Any Other Mechanical Equipment, Roll Ring Traverse Units Require Regular Maintenance And Occasional Troubleshooting To Prevent Downtime And Ensure Optimal Performance.

Proper Maintenance Of Roll Ring Traverse Units Is Essential To Prolong Their Lifespan And Prevent Costly Repairs. One Of The Most Important Maintenance Tasks Is Lubrication. Regularly Lubricating The Moving Parts Of The Unit Helps Reduce Friction And Wear, Ensuring Smooth Operation. It Is Recommended To Use A High-Quality Lubricant That Is Compatible With The Materials Used In The Unit To Prevent Damage.

In Addition To Lubrication, It Is Important To Regularly Inspect The Unit For Any Signs Of Wear Or Damage. Check For Loose Or Worn Parts, Misalignment, Or Any Unusual Noises During Operation. Addressing These Issues Promptly Can Prevent Further Damage And Extend The Life Of The Unit.

Another Important Aspect Of Maintaining Rolling ring linear drive Is Cleaning. Dust, Dirt, And Debris Can Accumulate On The Unit Over Time, Affecting Its Performance. Regularly Cleaning The Unit With A Soft Brush Or Cloth Can Help Prevent Buildup And Ensure Smooth Operation. Avoid Using Harsh Chemicals Or Abrasive Materials That Could Damage The Unit.

While Regular Maintenance Can Help Prevent Issues With Roll Ring Traverse Units, Occasional Troubleshooting May Still Be Necessary. One Common Issue That May Arise Is Misalignment Of The Unit. This Can Cause Uneven Winding Or Spooling Of Materials, Leading To Production Issues. To Troubleshoot Misalignment, Check For Any Loose Or Worn Parts And Adjust Them As Needed. It May Also Be Necessary To Realign The Unit To Ensure Proper Operation.

Another Common Issue With Roll Ring Traverse Units Is Slippage. This Can Occur When The Material Being Wound Or Spooled Does Not Move Smoothly Through The Unit, Causing Uneven Tension Or Winding. To Troubleshoot Slippage, Check For Any Obstructions Or Debris That May Be Causing The Issue. Adjust The Tension Settings As Needed To Ensure Proper Winding Of The Material.

In Some Cases, More Serious Issues May Arise With Roll Ring Traverse Units That Require Professional Repair. If You Encounter Any Issues That You Are Unable To Resolve On Your Own, It Is Recommended To Contact A Qualified Technician For Assistance. Attempting To Repair Complex Issues Without The Proper Knowledge Or Tools Can Cause Further Damage To The Unit.

In Conclusion, Proper Maintenance And Occasional Troubleshooting Are Essential For Ensuring The Smooth Operation Of Roll Ring Traverse Units In Manufacturing Processes. By Following These Tips And Guidelines, You Can Prevent Downtime, Extend The Lifespan Of The Unit, And Ensure Optimal Performance In Your Production Line. Remember To Regularly Lubricate, Inspect, And Clean The Unit, And Address Any Issues Promptly To Prevent Further Damage. If You Encounter Any Complex Issues, Seek Professional Assistance To Avoid Costly Repairs. With Proper Care And Maintenance, Your Roll Ring Traverse Unit Can Continue To Operate Efficiently And Effectively For Years To Come.