Table of Contents

Case Studies: Successful Implementation of Programmable traverse linear drives in Various Industries

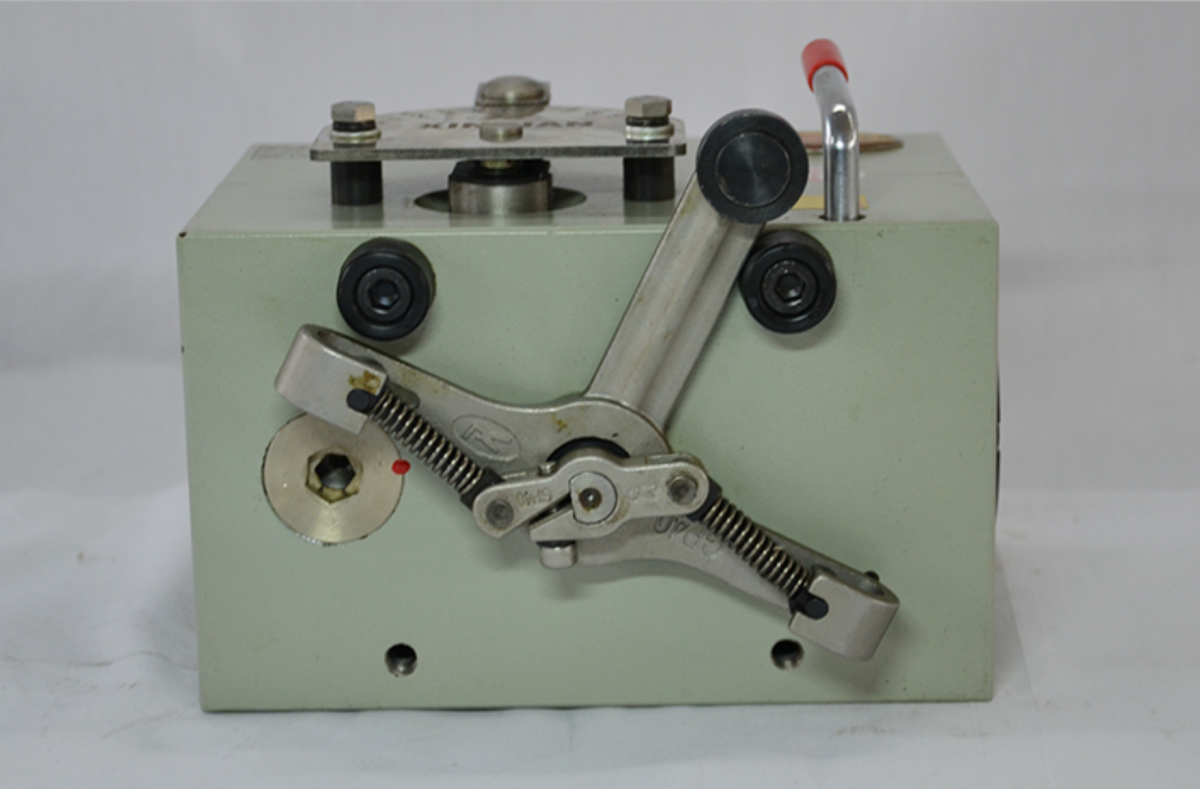

Programmable Rolling ring traverse drive has revolutionized the way industries operate by providing precise and efficient motion control solutions. These drives are programmable, meaning they can be customized to meet the specific needs of different applications. In this article, we will explore some case studies of successful implementation of programmable traverse linear drives in various industries.

One industry that has greatly benefited from the use of programmable traverse linear drives is the automotive industry. In the manufacturing process of automobiles, precision and accuracy are crucial. Programmable traverse linear drives have been used to automate various tasks such as welding, painting, and assembly. By programming the drives to move in a specific pattern, manufacturers can ensure that each component is placed in the correct position with high accuracy and repeatability.

Another industry that has seen success with programmable traverse linear drives is the aerospace industry. In the production of aircraft components, tight tolerances are required to ensure the safety and reliability of the final product. Programmable traverse linear drives have been used to machine complex shapes and contours with high precision. By programming the drives to follow a specific path, manufacturers can achieve the desired results with minimal error.

The medical industry is another sector that has embraced programmable traverse linear drives for various applications. In medical device manufacturing, precision is paramount to ensure the effectiveness of the devices. Programmable traverse linear drives have been used to automate tasks such as cutting, drilling, and engraving. By programming the drives to move in a specific sequence, manufacturers can produce high-quality medical devices with consistent results.

In the electronics industry, programmable Smooth Shaft Traverse Unit have been used for pick-and-place applications. In the assembly of electronic components, accuracy and speed are essential to meet the demands of the market. Programmable traverse linear drives have been programmed to pick up components from one location and place them in another with high precision. This automation has increased efficiency and productivity in the electronics manufacturing process.

The packaging industry has also seen successful implementation of programmable traverse linear drives. In the packaging of goods, speed and accuracy are key to meet the demands of consumers. Programmable traverse linear drives have been used to automate tasks such as filling, sealing, and labeling. By programming the drives to move in a specific sequence, manufacturers can package goods quickly and efficiently.

In conclusion, programmable traverse linear drives have proven to be a valuable asset in various industries. From automotive to aerospace, medical to electronics, and packaging, these drives have revolutionized the way tasks are automated and executed. By programming the drives to meet the specific needs of different applications, manufacturers can achieve high precision, accuracy, and efficiency in their operations. The successful implementation of programmable traverse linear drives in these industries is a testament to their versatility and effectiveness in improving productivity and quality.

How to Select the Right Programmable Traverse Linear Drive for Your Application

Programmable traverse linear drives are a crucial component in many industrial applications, providing precise and controlled movement along a linear axis. These drives are programmable, meaning that they can be customized to meet the specific requirements of a particular application. When selecting the right programmable traverse linear drive for your application, there are several key factors to consider.

One of the most important considerations when choosing a programmable traverse linear drive is the required speed and accuracy of movement. Different applications may require different levels of precision, so it is essential to select a drive that can meet the specific requirements of your application. Some drives are capable of high-speed movement, while others are designed for more precise positioning. By understanding the speed and accuracy requirements of your application, you can choose a drive that will provide the performance you need.

Another important factor to consider when selecting a Rolling ring drive is the load capacity. The drive must be able to support the weight of the load being moved along the linear axis. It is essential to choose a drive with a load capacity that exceeds the weight of the load to ensure smooth and reliable operation. Additionally, the drive should be able to handle any dynamic forces that may be present during operation, such as acceleration and deceleration.

In addition to speed, accuracy, and load capacity, it is also important to consider the environmental conditions in which the drive will be operating. Some drives are designed for use in cleanroom environments, while others are suitable for harsh industrial settings. By selecting a drive that is compatible with the environmental conditions of your application, you can ensure that it will perform reliably and efficiently.

When choosing a programmable traverse linear drive, it is also important to consider the available control options. Some drives come with built-in controllers, while others require an external controller to operate. The control options available will depend on the specific requirements of your application, so it is essential to choose a drive that offers the control capabilities you need.

Finally, it is important to consider the overall cost of the programmable traverse linear drive. The cost of the drive will depend on factors such as speed, accuracy, load capacity, and control options. By carefully considering these factors and comparing different drive options, you can choose a drive that provides the best value for your application.

In conclusion, selecting the right programmable traverse linear drive for your application requires careful consideration of factors such as speed, accuracy, load capacity, environmental conditions, control options, and cost. By understanding the specific requirements of your application and comparing different drive options, you can choose a drive that will provide the performance and reliability you need. With the right programmable traverse linear drive, you can ensure smooth and precise movement along a linear axis in your industrial application.