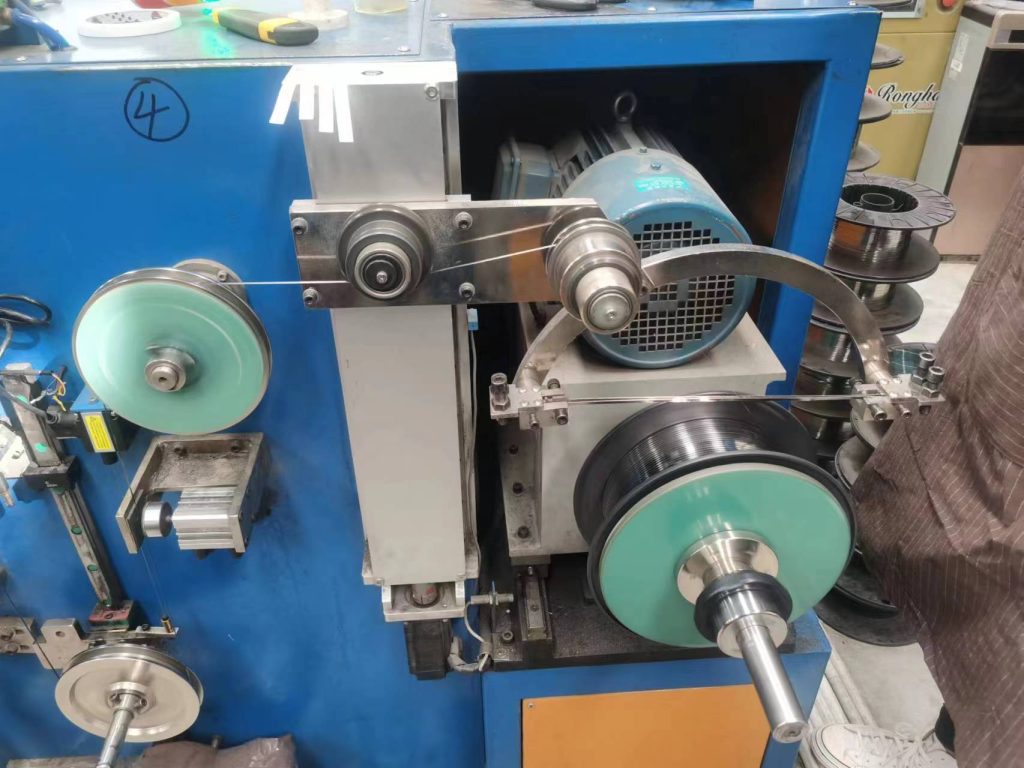

Precision Layer Winding Machine is Essential Tools In The Manufacturing Industry, Especially When It Comes To Handling Thin Wires. These Machines Are Designed To Wind Wires Onto Spools Or Bobbins With Utmost Accuracy And Precision, Ensuring That The Final Product Meets The Required Specifications. In This Article, We Will Explore The Benefits Of Using A For Thin Wires.

One Of The Key Advantages Of Using A Precision Layer Winding Machine Is The Ability To Achieve Consistent Winding Tension. Thin Wires Are Delicate And Can Easily Break If Wound Too Tightly Or Too Loosely. With A Precision Layer Winding Machine, The Tension Can Be Controlled And Adjusted To Ensure That The Wire Is Wound Evenly And Securely. This Helps To Prevent Any Damage To The Wire And Ensures A High-Quality End Product.

Another Benefit Of Using A precision wire layer winding machine Is The Ability To Achieve Uniform Winding Patterns. Thin Wires Are Often Used In Applications Where Precise Winding Patterns Are Required, Such As In The Production Of Coils Or Transformers. A Precision Layer Winding Machine Can Be Programmed To Create Specific Winding Patterns, Ensuring That Each Layer Is Wound Exactly As Needed. This Level Of Precision Is Difficult To Achieve Manually And Can Greatly Improve The Efficiency And Quality Of The Manufacturing Process.

In Addition To Consistent Tension And Uniform Winding Patterns, Precision Layer Winding Machines Also Offer Increased Productivity. These Machines Are Capable Of Winding Wires At A Much Faster Rate Than Manual Winding, Allowing Manufacturers To Produce More Products In Less Time. This Can Help To Reduce Production Costs And Improve Overall Efficiency In The Manufacturing Process.

Furthermore, Using A Precision Layer Winding Machine Can Also Help To Reduce Waste. When Wires Are Wound Manually, There Is A Higher Risk Of Errors And Inconsistencies, Which Can Result In Wasted Materials. By Using A Precision Layer Winding Machine, Manufacturers Can Minimize The Amount Of Waste Produced And Ensure That Each Spool Or Bobbin Is Filled To Its Maximum Capacity. This Not Only Helps To Save On Materials But Also Reduces The Need For Frequent Machine Adjustments And Maintenance.

Overall, The Benefits Of Using A Precision Layer Winding Machine For Thin Wires Are Clear. From Achieving Consistent Tension And Uniform Winding Patterns To Increasing Productivity And Reducing Waste, These Machines Offer A Range Of Advantages That Can Greatly Improve The Manufacturing Process. Whether You Are Producing Coils, Transformers, Or Any Other Product That Requires Precise Winding Of Thin Wires, Investing In A Precision Layer Winding Machine Is A Smart Choice That Can Help To Enhance The Quality And Efficiency Of Your Operations.