Table of Contents

Tips for Maximizing Efficiency with Double Reels Precision Layer Winding Machine

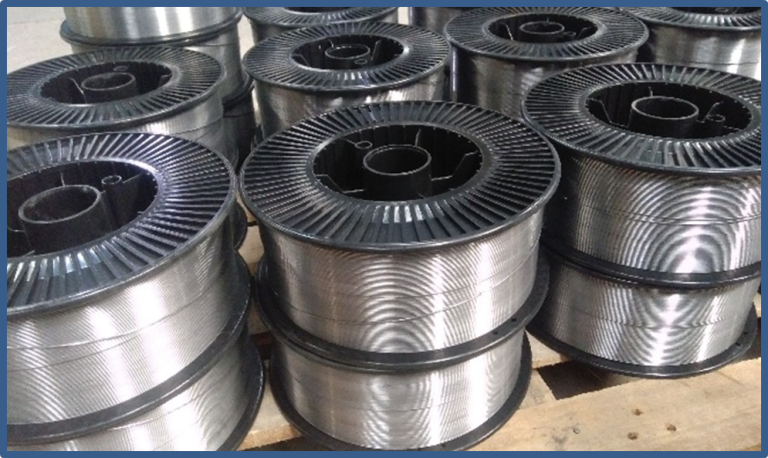

Double reels precision layer winding machine is essential tools in the manufacturing industry for efficiently winding materials onto spools or reels. These machines are designed to wind multiple materials simultaneously, increasing productivity and reducing downtime. To maximize efficiency with double reels precision layer winding machine, there are several tips that manufacturers can follow.

First and foremost, it is crucial to properly set up the machine before starting the winding process. This includes ensuring that the tension control system is calibrated correctly, the spools are aligned properly, and the materials are loaded onto the machine in the correct orientation. By taking the time to set up the machine correctly, manufacturers can avoid issues such as uneven winding, material breakage, and machine downtime.

Once the machine is set up, it is important to monitor the winding process closely to ensure that the materials are being wound onto the spools evenly and at the correct tension. This can be done by regularly checking the tension control system, inspecting the winding pattern, and making adjustments as needed. By monitoring the winding process, manufacturers can prevent issues such as overwinding, underwinding, and material slippage.

In addition to monitoring the winding process, it is also important to regularly maintain the machine to ensure optimal performance. This includes cleaning the machine regularly, lubricating moving parts, and replacing worn or damaged components. By keeping the machine well-maintained, manufacturers can prevent breakdowns, extend the machine’s lifespan, and ensure consistent winding quality.

Another tip for maximizing efficiency with Double Reels Precision Layer Winding Machines Are to optimize the winding speed and tension settings. By adjusting the winding speed and tension settings based on the type of material being wound, manufacturers can achieve faster winding speeds, reduce material waste, and improve winding quality. It is important to experiment with different settings to find the optimal combination for each material being wound.

Furthermore, it is important to train operators on how to use the double reels precision layer winding machine properly. This includes providing thorough training on machine operation, safety procedures, and troubleshooting techniques. By ensuring that operators are well-trained, manufacturers can prevent accidents, reduce downtime, and improve overall efficiency.

Lastly, it is important to regularly review and analyze production data to identify areas for improvement. By tracking key performance indicators such as production output, downtime, and material waste, manufacturers can identify trends, pinpoint inefficiencies, and implement corrective actions. By continuously monitoring and analyzing production data, manufacturers can optimize their processes, increase efficiency, and reduce costs.

In conclusion, double reels precision layer winding machines are valuable tools for manufacturers looking to increase productivity and efficiency in their winding processes. By following these tips for maximizing efficiency with double reels precision layer winding machines, manufacturers can achieve optimal performance, reduce downtime, and improve overall productivity. By properly setting up the machine, monitoring the winding process, maintaining the machine, optimizing settings, training operators, and analyzing production data, manufacturers can ensure that their double reels precision layer winding machines operate at peak efficiency.

Benefits of Using Double Reels Precision Layer Winding Machines

Double reels precision layer winding machines are a crucial piece of equipment in various industries that require precise winding of materials onto spools or reels. These machines offer a range of benefits that make them a valuable investment for businesses looking to improve their production processes and increase efficiency.

One of the key benefits of using double reels precision layer winding machines is their ability to ensure consistent and accurate winding of materials. These machines are equipped with advanced technology that allows them to control the tension and speed of the winding process, resulting in a uniform and tightly wound spool. This level of precision is essential for industries such as wire and cable manufacturing, where the quality of the winding can impact the performance of the final product.

In addition to precision winding, double reels precision layer winding machines also offer increased productivity and efficiency. These machines are designed to handle high volumes of materials and can wind multiple spools simultaneously, reducing the time and labor required for the winding process. This not only speeds up production but also allows businesses to meet tight deadlines and fulfill customer orders more quickly.

Furthermore, double reels precision layer winding machines are versatile and can be customized to meet the specific needs of different industries. Whether you are winding wire, cable, rope, or any other material, these machines can be adjusted to accommodate various spool sizes, winding patterns, and tension requirements. This flexibility makes them a valuable asset for businesses that work with a wide range of materials and products.

Another benefit of using double reels precision layer winding machines is their durability and reliability. These machines are built to withstand the rigors of continuous use and are constructed from high-quality materials that ensure long-term performance. This reliability is essential for businesses that rely on consistent production and cannot afford downtime due to equipment failures.

Additionally, double reels precision layer winding machines are easy to operate and maintain, making them a user-friendly option for businesses of all sizes. These machines are equipped with intuitive controls and interfaces that allow operators to quickly set up and adjust the winding process. Regular maintenance is also straightforward, ensuring that the machines remain in optimal condition and continue to deliver high-quality results.

Overall, the benefits of using double reels precision layer winding machines are clear. From precision winding and increased productivity to versatility and reliability, these machines offer a range of advantages that can help businesses improve their production processes and stay competitive in today’s fast-paced market. If you are looking to enhance your winding operations and streamline your production workflow, investing in a double reels precision layer winding machine may be the solution you need.