Tips For Maximizing Efficiency With DS800 Take-Up Machine

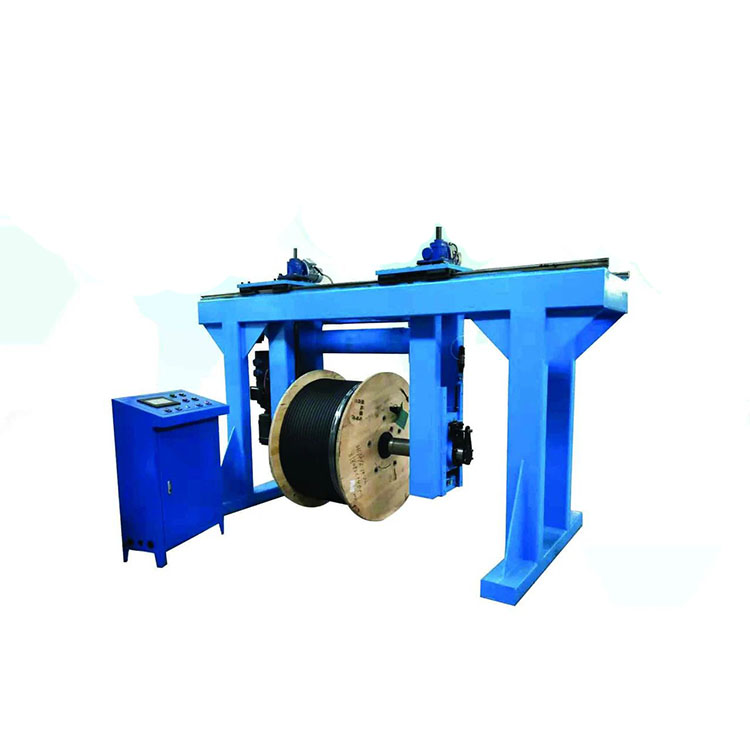

In The World Of Wire Winding, Efficiency Is Key. The DS800 Take-Up Machine For Special Wire Winding Is A Valuable Tool For Achieving This Efficiency, Especially When Working With Special Wires. Special Wires Can Present Unique Challenges Due To Their Composition Or Size, But With The Right Techniques, You Can Maximize The Efficiency Of Your DS800 Take-Up Machine And Produce High-Quality Wound Wire Products.

One Important Tip For Maximizing Efficiency With The DS800 Take-Up Machine Is To Ensure Proper Setup And Calibration. Before Beginning Any Winding Operation, It Is Crucial To Calibrate The Machine To The Specific Requirements Of The Wire Being Used. This Includes Setting The Appropriate Tension, Speed, And Winding Parameters To Ensure A Smooth And Consistent Winding Process. Proper Setup Will Not Only Improve The Quality Of The Wound Wire But Also Prevent Any Potential Damage To The Wire Or Machine.

Another Key Tip Is To Regularly Inspect And Maintain The DS800 Take-Up Machine. Like Any Piece Of Equipment, Regular Maintenance Is Essential For Optimal Performance. This Includes Cleaning The Machine, Checking For Any Loose Or Worn Parts, And Lubricating Moving Components. By Keeping The Machine In Good Working Condition, You Can Prevent Unexpected Breakdowns And Ensure Consistent And Reliable Operation.

When Working With Special Wires, It Is Important To Pay Attention To The Tension And Speed Settings Of The DS800 Take-Up Machine. Special Wires May Require Different Tension Levels Or Winding Speeds Compared To Standard Wires. By Adjusting These Settings Accordingly, You Can Prevent Any Potential Damage To The Wire And Achieve A More Precise And Uniform Winding Result.

Additionally, It Is Important To Monitor The Winding Process Closely When Working With Special Wires. Keep An Eye Out For Any Irregularities Or Inconsistencies In The Winding Pattern, As This Could Indicate A Problem With The Machine Or Wire. By Staying Vigilant During The Winding Process, You Can Quickly Address Any Issues That Arise And Ensure A High-Quality End Product.

One Final Tip For Maximizing Efficiency With The DS800 Take-Up Machine Is To Invest In Proper Training For Operators. Proper Training Is Essential For Ensuring That Operators Understand How To Use The Machine Effectively And Safely. By Providing Comprehensive Training, You Can Improve The Overall Efficiency Of The Winding Process And Reduce The Risk Of Errors Or Accidents.

In Conclusion, The DS800 Take-Up Machine Is A Valuable Tool For Winding Special Wires Efficiently. By Following These Tips, You Can Maximize The Efficiency Of The Machine And Produce High-Quality Wound Wire Products. Proper Setup And Calibration, Regular Maintenance, Attention To Tension And Speed Settings, Close Monitoring Of The Winding Process, And Investing In Operator Training Are All Essential For Achieving Optimal Results With The DS800 Take-Up Machine. With These Tips In Mind, You Can Streamline Your Wire Winding Operations And Achieve Greater Efficiency And Productivity.