Table of Contents

Advantages Of Using Rolling Ring Drives In Industrial Applications

Rolling Ring Drives Are A Type Of Linear Motion Drive System That Is Similar To The More Commonly Known Uhing Rolling ring drive. These Drives Offer A Number Of Advantages When Used In Industrial Applications, Making Them A Popular Choice For Many Manufacturers.

One Of The Key Advantages Of Rolling Ring Drives Is Their Simplicity And Reliability. Unlike Other Linear Motion Systems That Rely On Complex Mechanisms And Components, Rolling Ring Drives Have A Simple Design That Is Easy To Understand And Maintain. This Makes Them Less Prone To Failure And Reduces The Need For Frequent Maintenance, Saving Both Time And Money For Industrial Users.

In Addition To Their Simplicity, Rolling Ring Drives Also Offer High Precision And Accuracy In Motion Control. The Rolling Ring Mechanism Allows For Smooth And Precise Linear Motion, Making Them Ideal For Applications That Require Precise Positioning And Control. This Level Of Precision Is Essential In Many Industrial Processes, Such As Assembly Lines And Packaging Systems, Where Even Small Errors Can Have A Significant Impact On Product Quality And Efficiency.

Another Advantage Of Rolling Ring Drives Is Their Versatility. These Drives Can Be Easily Adapted To A Wide Range Of Applications, Thanks To Their Modular Design And Customizable Options. This Flexibility Allows Manufacturers To Tailor The Drive System To Meet Their Specific Needs, Whether That Involves Adjusting The Speed, Stroke Length, Or Mounting Configuration. This Adaptability Makes Rolling Ring Drives A Versatile And Cost-Effective Solution For A Variety Of Industrial Applications.

Furthermore, Rolling Ring Drives Are Known For Their High Efficiency And Energy Savings. The Rolling Ring Mechanism Minimizes Friction And Wear, Resulting In Smooth And Efficient Motion That Requires Less Energy To Operate. This Not Only Reduces Operating Costs But Also Helps To Prolong The Lifespan Of The Drive System, Making It A Sustainable Choice For Environmentally Conscious Manufacturers.

Additionally, Rolling Ring Drives Are Durable And Long-Lasting, Thanks To Their Robust Construction And High-Quality Materials. These Drives Are Designed To Withstand The Rigors Of Industrial Use, Including Heavy Loads, High Speeds, And Harsh Operating Conditions. This Durability Ensures That Rolling Ring Drives Can Provide Reliable Performance Over An Extended Period Of Time, Reducing The Need For Frequent Replacements And Repairs.

In Conclusion, Rolling Ring Drives Offer A Number Of Advantages For Industrial Applications, Including Simplicity, Precision, Versatility, Efficiency, And Durability. These Drives Are A Reliable And Cost-Effective Solution For Manufacturers Looking To Improve Their Motion Control Systems And Enhance Productivity. With Their Proven Track Record And Numerous Benefits, Rolling Ring Drives Are A Popular Choice For A Wide Range Of Industrial Applications.

How Rolling Ring Drives Compare To Other Linear Motion Technologies

Rolling Ring Drives Are A Type Of Linear Motion Technology That Is Often Compared To Other Similar Technologies In The Industry. One Such Technology That Is Often Compared To Rolling Ring Drives Is The Uhing Rolling Ring Drive. While Both Technologies Serve The Same Purpose Of Providing Linear Motion, There Are Some Key Differences Between The Two That Make Them Suitable For Different Applications.

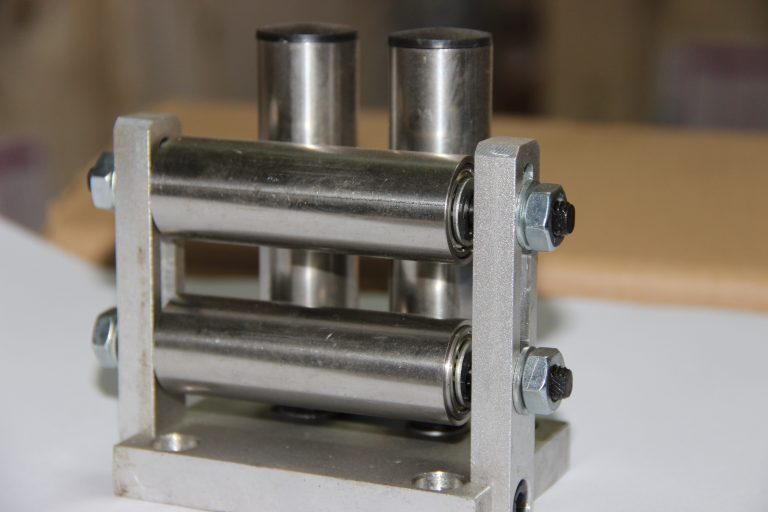

One Of The Main Differences Between Rolling Ring Drives And Uhing rolling ring Drives Is The Design Of The Drive Mechanism. Rolling Ring Drives Use A Set Of Rolling Rings That Are Mounted On A Shaft And Are Driven By A Rotating Drum. This Design Allows For Smooth And Precise Linear Motion, Making Rolling Ring Drives Ideal For Applications That Require High Accuracy And Repeatability.

On The Other Hand, Uhing Rolling Ring Drives Use A Different Design That Incorporates A Threaded Shaft And A Nut That Moves Along The Shaft To Provide Linear Motion. This Design Allows For Greater Flexibility In Terms Of Speed And Acceleration, Making Uhing Rolling Ring Drives Suitable For Applications That Require Dynamic Motion Control.

Another Key Difference Between Rolling Ring Drives And Uhing Rolling Ring Drives Is The Load Capacity Of The Drives. Rolling Ring Drives Are Typically Designed To Handle Lighter Loads, Making Them Suitable For Applications That Require Precise Positioning Of Small Components. Uhing Rolling Ring Drives, On The Other Hand, Are Capable Of Handling Heavier Loads, Making Them Ideal For Applications That Require Moving Larger Components Or Materials.

In Terms Of Cost, Rolling Ring Drives Are Generally More Affordable Than Uhing Rolling Ring Drives. This Makes Rolling Ring Drives A Cost-Effective Solution For Applications That Require Precise Linear Motion On A Budget. Uhing Rolling Ring Drives, While More Expensive, Offer Greater Flexibility And Performance Capabilities, Making Them A Better Choice For Applications That Require More Advanced Motion Control.