Table of Contents

Comparison of Different Roll Ring Traverse Unit Models and Brands

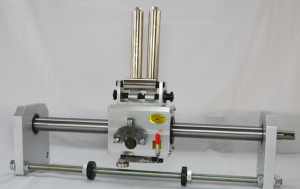

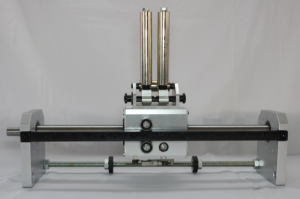

Rolling ring traverse drive is essential components in various industrial applications, providing precise and consistent winding of materials onto spools or reels. These units are designed to ensure uniform distribution of the material being wound, resulting in high-quality finished products. When it comes to selecting a roll ring traverse unit, there are several models and brands available on the market, each offering unique features and capabilities. In this article, we will compare different roll ring traverse unit models and brands to help you make an informed decision for your specific application.

One popular brand of roll ring traverse units is the Cortec Corporation, known for its high-quality and reliable products. Cortec offers a range of models, including the CR Series and the TR Series, each designed to meet the specific needs of different industries. The CR Series is ideal for applications requiring high-speed winding, while the TR Series is more suited for precision winding of delicate materials. Both series feature durable construction and advanced technology to ensure smooth and efficient operation.

Another well-known brand in the roll ring traverse unit market is the Sonobond Ultrasonics, which specializes in ultrasonic technology for bonding and sealing applications. Sonobond offers the SonoWeld series of roll ring traverse units, which utilize ultrasonic welding technology to provide superior bonding strength and consistency. These units are ideal for applications requiring airtight seals or secure bonding of materials, such as in the medical or automotive industries.

For those looking for a more budget-friendly option, the Tidland Corporation offers the e-Knife series of roll ring traverse units, which provide reliable performance at a lower cost. The e-Knife series features a simple design with easy-to-use controls, making it ideal for small to medium-sized businesses with limited budgets. Despite its affordability, the e-Knife series still delivers consistent winding performance and durability, making it a popular choice among budget-conscious consumers.

In terms of features and capabilities, each brand and model of roll ring traverse unit offers unique advantages. For example, the Cortec CR Series is known for its high-speed winding capabilities, making it ideal for applications requiring rapid production. On the other hand, the Sonobond SonoWeld series excels in precision bonding and sealing applications, thanks to its ultrasonic welding technology. The Tidland e-Knife series, while more basic in design, still provides reliable performance and ease of use for small businesses.

When choosing a Roll ring traverse drive for your application, it is important to consider factors such as speed, precision, durability, and budget. Each brand and model offers different strengths and capabilities, so it is essential to evaluate your specific requirements before making a decision. Whether you prioritize high-speed production, precision winding, or cost-effectiveness, there is a roll ring traverse unit out there to meet your needs.

In conclusion, the roll ring traverse unit market offers a variety of models and brands to choose from, each with its own unique features and capabilities. Whether you opt for the high-speed performance of the Cortec CR Series, the precision bonding of the Sonobond SonoWeld series, or the budget-friendly option of the Tidland e-Knife series, there is a roll ring traverse unit to suit your specific application. By carefully evaluating your requirements and comparing different models and brands, you can select the best roll ring traverse unit for your industrial needs.

Benefits of Using Roll Ring Traverse Unit in Industrial Applications

Roll ring traverse units are essential components in various industrial applications, providing a reliable and efficient way to guide materials through a production process. These units offer a range of benefits that make them a popular choice for manufacturers looking to improve their operations.

One of the key advantages of using a Rolling ring drive is its ability to provide precise and consistent material guidance. This is crucial in industries where accuracy is paramount, such as in the production of electronic components or medical devices. The roll ring traverse unit ensures that materials are guided along a predetermined path, reducing the risk of errors and ensuring that products meet strict quality standards.

In addition to precision, roll ring traverse units also offer versatility in terms of the types of materials they can handle. Whether it’s paper, plastic, metal, or fabric, these units can effectively guide a wide range of materials through the production process. This flexibility makes them a valuable asset for manufacturers working with diverse materials and products.

Another benefit of using a roll ring traverse unit is its durability and reliability. These units are built to withstand the rigors of industrial environments, ensuring consistent performance even in demanding conditions. This reliability minimizes downtime and maintenance costs, allowing manufacturers to focus on their core operations without worrying about equipment failures.

Furthermore, roll ring traverse units are designed for easy integration into existing production lines. Whether it’s a new installation or a retrofit, these units can be seamlessly integrated into a variety of production setups, minimizing disruption and ensuring a smooth transition. This flexibility makes them a cost-effective solution for manufacturers looking to improve their operations without significant investment in new equipment.

In addition to their technical benefits, roll ring traverse units also offer economic advantages for manufacturers. By improving material guidance and reducing errors, these units can help increase production efficiency and reduce waste. This translates into cost savings and improved profitability for businesses, making roll ring traverse units a smart investment for companies looking to optimize their operations.

Overall, the benefits of using a roll ring traverse unit in industrial applications are clear. From precision and versatility to durability and cost-effectiveness, these units offer a range of advantages that can help manufacturers improve their production processes and achieve better results. Whether it’s guiding materials through a complex manufacturing process or ensuring consistent quality in the final product, roll ring traverse units are an essential tool for modern industrial operations.

How to Properly Maintain and Troubleshoot Roll Ring Traverse Unit

Roll ring traverse units are essential components in various industrial applications, including wire winding, cable manufacturing, and textile machinery. These units play a crucial role in ensuring the smooth and efficient operation of the production process. However, like any other mechanical equipment, roll ring traverse units require regular maintenance to ensure optimal performance and prevent costly downtime. In this article, we will discuss how to properly maintain and troubleshoot roll ring traverse units to maximize their lifespan and efficiency.

One of the most important aspects of maintaining a Smooth Shaft Traverse Unit is ensuring that it is properly lubricated. Lubrication helps reduce friction between moving parts, preventing wear and tear and extending the life of the unit. It is essential to use the correct type of lubricant recommended by the manufacturer and to follow the recommended lubrication schedule. Regularly checking the lubrication levels and topping up as needed will help prevent premature failure of the unit.

In addition to lubrication, it is important to regularly inspect the roll ring traverse unit for any signs of wear or damage. This includes checking for loose or worn bearings, misaligned components, and any unusual noises or vibrations during operation. Any issues should be addressed promptly to prevent further damage and ensure the continued smooth operation of the unit.

Another important aspect of maintaining a roll ring traverse unit is keeping it clean and free of debris. Dust, dirt, and other contaminants can build up on the unit over time, causing it to operate less efficiently and potentially leading to malfunctions. Regularly cleaning the unit with a soft brush or cloth and removing any debris will help prevent these issues and prolong the life of the unit.

When troubleshooting a roll ring traverse unit, it is important to start by identifying the source of the problem. This may involve checking for loose or damaged components, inspecting the lubrication levels, and listening for any unusual noises during operation. Once the source of the issue has been identified, appropriate steps can be taken to address it.

Common issues that may arise with roll ring traverse units include misalignment, bearing failure, and excessive wear. Misalignment can cause the unit to operate inefficiently and lead to premature failure of components. Bearing failure can result in increased friction and wear, while excessive wear can cause the unit to operate less smoothly and potentially lead to malfunctions. By addressing these issues promptly and effectively, the lifespan and efficiency of the unit can be maximized.

In conclusion, proper maintenance and troubleshooting of roll ring traverse units are essential for ensuring their optimal performance and longevity. By following the recommended maintenance schedule, keeping the unit clean and well-lubricated, and promptly addressing any issues that arise, the lifespan of the unit can be extended, and costly downtime can be minimized. By taking care of these essential components, industrial processes can continue to operate smoothly and efficiently, leading to increased productivity and profitability.