Table of Contents

Advantages of Using Programmable Traverse Drive Unit in Industrial Automation

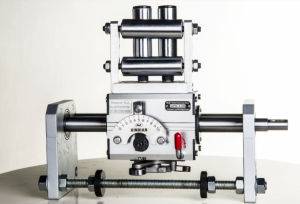

In the world of industrial automation, efficiency and precision are key factors in ensuring Smooth Shaft Unit operations and maximizing productivity. One technology that has revolutionized the way machines operate is the programmable traverse drive unit. This innovative system allows for precise control and movement of various components in industrial machinery, offering a wide range of advantages for manufacturers and operators.

One of the primary advantages of using a programmable Rolling ring traverse drive unit is the ability to customize and program the movement of the drive unit to suit specific requirements. This level of flexibility allows for greater control over the speed, direction, and distance of the drive unit, ensuring that it can perform a wide range of tasks with precision and accuracy. This level of customization is particularly useful in industries where complex movements are required, such as in the manufacturing of electronic components or in the automotive industry.

Another key advantage of using a programmable traverse drive unit is the ability to automate repetitive tasks, reducing the need for manual intervention and minimizing the risk of human error. By programming the drive unit to perform specific movements automatically, operators can focus on other tasks that require more attention, leading to increased efficiency and productivity. This automation also helps to reduce the risk of injuries and accidents in the workplace, as operators are not required to perform repetitive and potentially dangerous tasks.

In addition to automation, Rolling ring linear drive units also offer improved accuracy and consistency in operations. By programming the drive unit to follow a specific path or trajectory, manufacturers can ensure that each movement is performed with the same level of precision every time. This level of consistency is crucial in industries where even the smallest deviation can lead to costly errors or defects in the final product. By using a programmable traverse drive unit, manufacturers can guarantee that their operations meet the highest standards of quality and reliability.

Furthermore, programmable traverse drive units are also highly versatile and can be easily integrated into existing machinery and systems. This flexibility allows manufacturers to upgrade their equipment without having to invest in entirely new systems, saving time and money in the long run. Additionally, the ability to program the drive unit to perform multiple tasks means that manufacturers can adapt to changing production requirements quickly and efficiently, ensuring that their operations remain competitive and up-to-date.

Overall, the advantages of using a programmable traverse drive unit in industrial automation are clear. From increased customization and automation to improved accuracy and versatility, this technology offers a wide range of benefits for manufacturers and operators alike. By incorporating programmable traverse drive units into their operations, companies can streamline their processes, increase productivity, and maintain a competitive edge in today’s fast-paced industrial landscape.

How to Optimize Performance of Programmable Traverse Drive Unit in Manufacturing Processes

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of any operation. One technology that has revolutionized the way manufacturing processes are carried out is the programmable traverse drive unit. This innovative piece of equipment allows for precise control over the movement of materials, resulting in increased productivity and improved quality of the final product.

To optimize the performance of a programmable roll ring drive unit, it is essential to understand how it works and how it can be integrated into existing manufacturing processes. Essentially, a traverse drive unit is a motorized system that moves a carriage along a track or rail, allowing for precise positioning of materials or tools. By programming the unit with specific instructions, manufacturers can automate the movement of materials, reducing the need for manual labor and minimizing the risk of human error.

One of the key benefits of using a programmable traverse drive unit is the ability to achieve consistent and repeatable results. By programming the unit to follow a specific path or trajectory, manufacturers can ensure that materials are moved with precision and accuracy every time. This not only improves the quality of the final product but also reduces waste and rework, ultimately saving time and money in the long run.

Another advantage of using a programmable traverse drive unit is the flexibility it offers in terms of customization. Manufacturers can program the unit to move materials in a variety of ways, including straight lines, curves, and complex patterns. This allows for greater versatility in manufacturing processes, enabling manufacturers to adapt to changing production requirements and optimize their operations for maximum efficiency.

To further optimize the performance of a programmable traverse drive unit, manufacturers should consider integrating it with other automation technologies, such as robotic arms or conveyor systems. By synchronizing the movement of materials across different systems, manufacturers can streamline their processes and achieve even greater levels of efficiency. Additionally, by connecting the traverse drive unit to a centralized control system, manufacturers can monitor and adjust its performance in real-time, ensuring that it operates at peak efficiency at all times.

In conclusion, the programmable traverse drive unit is a valuable tool for manufacturers looking to optimize their production processes. By understanding how the unit works and how it can be integrated with other automation technologies, manufacturers can achieve consistent and repeatable results, improve the quality of their products, and increase overall efficiency. With the right approach and attention to detail, manufacturers can unlock the full potential of the programmable traverse drive unit and take their manufacturing operations to the next level.