Table of Contents

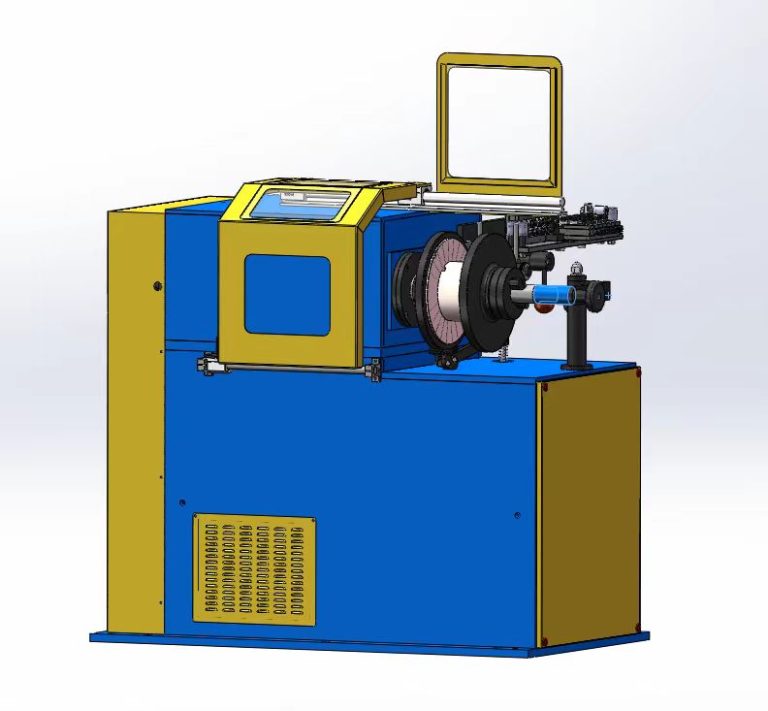

Double Reels Precision Layer Winding Machine

In the world of manufacturing, precision and efficiency are key factors in ensuring high-quality products are produced in a timely manner. One piece of equipment that plays a crucial role in achieving these goals is the Double Reels Precision Layer Winding Machine. This innovative machine offers a range of benefits that can greatly improve the production process for a variety of industries.

One of the primary benefits of using a Double Reels Precision Layer Winding Machine is its ability to accurately wind materials onto reels with precision. This is essential for industries that require precise measurements and consistent winding patterns, such as the textile and wire industries. The machine is equipped with advanced technology that allows for precise control over the winding process, ensuring that each layer is wound evenly and securely.

Another key benefit of the Double Reels Precision Layer Winding Machine is its efficiency. By automating the winding process, the machine can significantly reduce the time and labor required to wind materials onto reels. This not only increases productivity but also reduces the risk of human error, resulting in higher quality products. Additionally, the machine can be programmed to wind materials at different speeds and tension levels, allowing for greater flexibility in the production process.

In addition to its precision and efficiency, the Double Reels Precision Layer Winding Machine also offers a number of other benefits. For example, the machine is designed to be user-friendly, with intuitive controls and easy maintenance procedures. This makes it easy for operators to learn how to use the machine quickly and efficiently, reducing downtime and increasing overall productivity.

Furthermore, the machine is built to last, with durable materials and components that can withstand the rigors of continuous use. This ensures that the machine will provide reliable performance for years to come, making it a sound investment for any manufacturing operation. Additionally, the machine is designed to be energy-efficient, helping to reduce operating costs and minimize environmental impact.

Overall, the Double Reels Precision Layer Winding Machine offers a range of benefits that can greatly improve the production process for a variety of industries. From its precision winding capabilities to its efficiency and durability, this machine is a valuable asset for any manufacturing operation looking to increase productivity and quality. By investing in a Double Reels Precision Layer Winding Machine, companies can streamline their production process and achieve greater success in today’s competitive market.

Tips for Maximizing Efficiency with Double Reels Precision Layer Winding Machine

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes and maximize productivity. One way to achieve this is by utilizing advanced machinery, such as the Double Reels Precision Layer Winding Machine. This state-of-the-art equipment is designed to wind multiple reels of material simultaneously, allowing for faster production and higher output. However, in order to truly maximize efficiency with this machine, there are a few tips and tricks that manufacturers should keep in mind.

First and foremost, it is important to properly set up the Double Reels Precision Layer Winding Machine. This includes ensuring that all reels are loaded correctly and securely, and that the machine is calibrated to the appropriate specifications for the material being wound. Taking the time to properly set up the machine at the beginning of each production run will help to prevent issues and delays down the line.

Another key tip for maximizing efficiency with the Double Reels Precision Layer Winding Machine is to monitor the process closely. This means keeping a close eye on the tension of the material being wound, as well as the speed and alignment of the reels. By monitoring these factors regularly, operators can quickly identify any issues that may arise and make adjustments as needed to keep the production line running smoothly.

Additionally, it is important to properly maintain the Double Reels Precision Layer Winding Machine in order to ensure optimal performance. This includes regularly cleaning and lubricating the machine, as well as replacing any worn or damaged parts. By keeping the machine in good working condition, manufacturers can avoid costly breakdowns and downtime, allowing for uninterrupted production.

One of the most important tips for maximizing efficiency with the Double Reels Precision Layer Winding Machine is to train operators properly. This includes providing thorough training on how to operate the machine safely and effectively, as well as educating them on best practices for maximizing productivity. By investing in proper training for operators, manufacturers can ensure that the machine is being used to its full potential, leading to increased efficiency and output.

Finally, it is important to continuously evaluate and improve processes when using the Double Reels Precision Layer Winding Machine. This includes analyzing production data, identifying areas for improvement, and implementing changes to streamline operations. By constantly striving for improvement, manufacturers can stay ahead of the competition and continue to maximize efficiency with this advanced machinery.

In conclusion, the Double Reels Precision Layer Winding Machine is a valuable tool for manufacturers looking to increase efficiency and productivity. By following these tips and best practices, companies can make the most of this advanced equipment and achieve optimal results in their production processes. With proper setup, monitoring, maintenance, training, and continuous improvement, manufacturers can maximize efficiency with the Double Reels Precision Layer Winding Machine and stay ahead in today’s competitive manufacturing landscape.