Table of Contents

Advantages of Using Rolling ring linear drive for Precision Applications

Rolling ring linear drive is a popular choice for precision applications due to their unique design and numerous advantages. These drives consist of a rotating ring that moves along a threaded shaft, providing smooth and precise linear motion. In this article, we will explore the advantages of using Rolling ring drive for precision applications.

One of the key advantages of rolling ring linear drive is their high level of precision. The rotating ring moves along the threaded shaft with minimal backlash, ensuring accurate positioning and repeatability. This makes rolling ring linear drive ideal for applications that require precise motion control, such as in the medical, semiconductor, and aerospace industries.

In addition to their precision, Rolling ring traverse drive also offer high speed capabilities. The rotating ring can move at speeds of up to 10 meters per second, making them suitable for applications that require fast and efficient motion. This high speed capability allows for increased productivity and throughput in manufacturing processes.

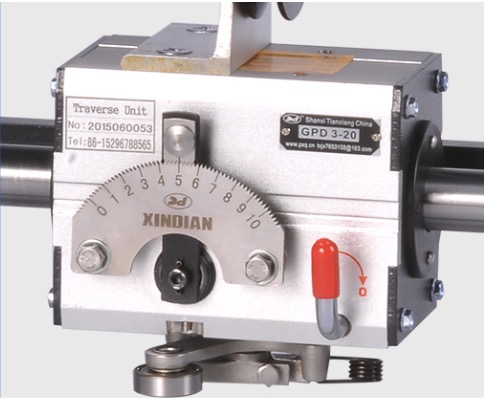

Another advantage of rolling ring linear drive is their compact and lightweight design. The drives have a small footprint and low profile, making them easy to integrate into tight spaces and existing machinery. Their lightweight construction also reduces the overall weight of the system, making them ideal for applications where weight is a concern.

rolling ring Linear drives are also known for their durability and reliability. The drives are made from high-quality materials that can withstand harsh operating conditions, such as high temperatures, dust, and vibrations. This ensures that the drives will perform consistently and reliably over time, reducing maintenance and downtime.

Furthermore, rolling ring linear drives are easy to install and maintain. The drives can be quickly and easily mounted onto existing equipment, saving time and labor costs. Additionally, the drives require minimal maintenance, with only periodic lubrication needed to ensure smooth operation.

Overall, rolling ring linear drives offer numerous advantages for precision applications. Their high level of precision, high speed capabilities, compact design, durability, and ease of installation and maintenance make them an ideal choice for a wide range of industries. Whether you are in the medical, semiconductor, aerospace, or any other industry that requires precise motion control, rolling ring linear drives are a reliable and efficient solution.

If you are in need of a rolling ring linear drive for your precision application, be sure to check out our selection of drives for sale. With their numerous advantages and high-quality construction, you can trust that a rolling ring linear drive will meet your needs and exceed your expectations.

How to Choose the Right Rolling Ring Linear Drive for Your Specific Needs

Rolling ring linear drives are a popular choice for many industrial applications due to their simplicity, reliability, and precision. If you are in the market for a rolling ring linear drive, it is important to choose the right one for your specific needs. With so many options available, it can be overwhelming to make a decision. In this article, we will discuss some key factors to consider when selecting a rolling ring linear drive to ensure that you choose the best option for your application.

One of the first things to consider when choosing a rolling ring linear drive is the load capacity. It is important to select a drive that can handle the weight of the load that it will be moving. If the drive is not able to support the load, it can lead to premature wear and failure. Be sure to carefully calculate the weight of your load and choose a drive with a load capacity that exceeds this weight to ensure optimal performance.

Another important factor to consider is the speed and acceleration requirements of your application. Different rolling ring linear drives have different maximum speeds and acceleration capabilities. It is important to choose a drive that can meet the speed and acceleration requirements of your specific application. If the drive is not able to move the load at the required speed or acceleration, it can lead to inefficiency and decreased productivity.

In addition to load capacity and speed requirements, it is also important to consider the precision and repeatability of the rolling ring linear drive. Precision is crucial in many industrial applications where accuracy is paramount. Choose a drive that offers the level of precision required for your application to ensure that your processes run smoothly and efficiently. Repeatability is also important, as it ensures that the drive can consistently move the load to the same position every time.

When selecting a rolling ring linear drive, it is also important to consider the environmental conditions in which the drive will be operating. Some drives are better suited for harsh environments with high temperatures, dust, or moisture. Be sure to choose a drive that is designed to withstand the specific environmental conditions of your application to ensure longevity and reliability.

Finally, it is important to consider the overall cost of the rolling ring linear drive. While it may be tempting to choose the least expensive option, it is important to consider the long-term costs associated with maintenance, repairs, and downtime. Choose a drive that offers a good balance of performance and cost to ensure that you get the best value for your investment.

In conclusion, choosing the right rolling ring linear drive for your specific needs requires careful consideration of factors such as load capacity, speed and acceleration requirements, precision and repeatability, environmental conditions, and overall cost. By taking the time to evaluate these factors and choose a drive that meets your requirements, you can ensure that your application runs smoothly and efficiently.