Table of Contents

Advantages of Using Mechanical Rolling ring drive Type in Industrial Applications

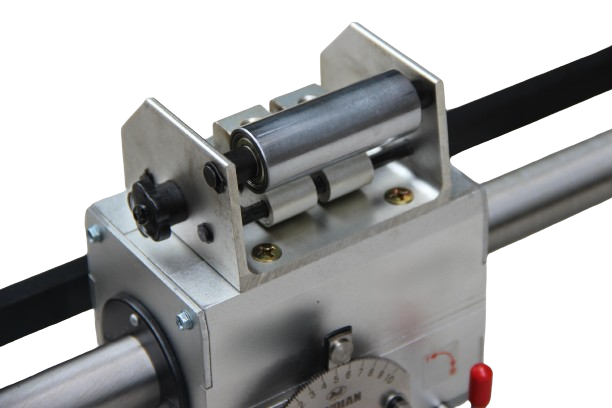

Mechanical Rolling Ring Drives are a type of mechanical transmission system that is commonly used in industrial applications. These drives offer a number of advantages that make them a popular choice for many different types of machinery and equipment. In this article, we will explore some of the key benefits of using mechanical rolling ring drives in industrial settings.

One of the primary advantages of mechanical rolling ring drives is their high efficiency. These drives are able to transmit power from one component to another with minimal energy loss, making them an ideal choice for applications where energy efficiency is a priority. This efficiency can help to reduce operating costs and improve overall system performance.

Another key advantage of mechanical rolling ring drives is their durability and reliability. These drives are designed to withstand heavy loads and harsh operating conditions, making them well-suited for use in industrial environments where equipment is subjected to high levels of stress and wear. This durability helps to extend the lifespan of the equipment and reduce the need for frequent maintenance and repairs.

In addition to their efficiency and durability, mechanical Rolling ring linear drive also offer a high degree of precision and control. These drives are able to provide smooth and accurate motion control, allowing for precise positioning and movement of machinery and equipment. This level of control is essential in many industrial applications where precision is critical to the success of the operation.

Furthermore, mechanical rolling ring drives are versatile and can be easily adapted to a wide range of applications. These drives can be customized to meet the specific requirements of different types of machinery and equipment, making them a flexible and adaptable choice for industrial applications. This versatility allows for greater flexibility in design and implementation, making it easier to integrate mechanical rolling ring drives into existing systems.

One of the key advantages of mechanical rolling ring drives is their compact size and lightweight design. These drives are able to provide high levels of power transmission in a small and lightweight package, making them ideal for use in applications where space is limited or weight is a concern. This compact design also helps to reduce the overall footprint of the equipment, making it easier to install and integrate into existing systems.

In conclusion, mechanical rolling ring drives offer a number of advantages that make them a popular choice for industrial applications. From their high efficiency and durability to their precision and control, these drives provide a reliable and versatile solution for a wide range of machinery and equipment. With their compact size and lightweight design, mechanical rolling ring drives are well-suited for use in applications where space and weight are a concern. Overall, mechanical rolling ring drives are a cost-effective and efficient option for industrial applications that require reliable power transmission and precise motion control.

How to Properly Maintain and Care for Mechanical Rolling Ring Drives Type

Mechanical rolling ring drives are a type of mechanical transmission system that is commonly used in various industrial applications. These drives are known for their high efficiency, precision, and reliability. However, like any other mechanical system, they require proper maintenance and care to ensure optimal performance and longevity.

One of the most important aspects of maintaining mechanical rolling ring drives is regular lubrication. Proper lubrication helps reduce friction and wear between moving parts, which in turn extends the life of the drive system. It is essential to use the right type of lubricant and to follow the manufacturer’s recommendations for lubrication intervals.

In addition to lubrication, it is also important to regularly inspect the drive system for any signs of wear or damage. This includes checking for loose or worn components, misalignment, and excessive vibration. Any issues should be addressed promptly to prevent further damage and ensure the drive system continues to operate smoothly.

Another key aspect of maintaining mechanical rolling ring drives is proper alignment. Misalignment can cause excessive wear on the drive components and lead to premature failure. It is important to check the alignment of the drive system regularly and make any necessary adjustments to ensure that all components are properly aligned.

Furthermore, it is important to keep the drive system clean and free of debris. Dust, dirt, and other contaminants can cause damage to the drive components and affect the overall performance of the system. Regular cleaning and inspection can help prevent these issues and ensure the drive system operates at its best.

When it comes to caring for mechanical Rolling-ring drives, it is also important to operate the system within its specified limits. Overloading the drive system can cause excessive stress on the components and lead to premature failure. It is important to follow the manufacturer’s recommendations for load capacity and operating conditions to ensure the drive system operates safely and efficiently.

In addition to regular maintenance and care, it is also important to keep accurate records of all maintenance activities and inspections. This can help track the performance of the drive system over time and identify any patterns or trends that may indicate potential issues. Keeping detailed records can also help ensure that maintenance activities are performed on schedule and that the drive system remains in optimal condition.

In conclusion, proper maintenance and care are essential for ensuring the optimal performance and longevity of mechanical rolling ring drives. Regular lubrication, inspection, alignment, cleaning, and operating within specified limits are all key aspects of maintaining these drive systems. By following these guidelines and keeping accurate records of maintenance activities, you can help ensure that your mechanical rolling ring drives continue to operate smoothly and reliably for years to come.

Comparison of Mechanical Rolling Ring Drives Type with Other Types of Mechanical Drives

Mechanical rolling ring drives are a type of mechanical drive system that offers unique advantages compared to other types of mechanical drives. In this article, we will explore the features and benefits of mechanical rolling ring drives and compare them to other types of mechanical drives.

One of the key advantages of mechanical rolling ring drives is their ability to provide precise and repeatable linear motion. This is achieved through the use of a rolling ring bearing that allows for smooth and accurate movement along a linear axis. This level of precision is essential in many applications, such as in the medical and semiconductor industries, where accuracy is critical.

Another advantage of mechanical Smooth Shaft Unit is their compact size and lightweight design. This makes them ideal for applications where space is limited or where weight is a concern. In comparison, other types of mechanical drives, such as ball screws or belt drives, can be bulkier and heavier, making them less suitable for certain applications.

In addition to their precision and compact design, mechanical rolling ring drives also offer high efficiency and low maintenance requirements. The rolling ring bearing design minimizes friction and wear, resulting in a drive system that operates smoothly and reliably over time. This can lead to cost savings in terms of maintenance and replacement parts.

When compared to other types of mechanical drives, such as ball screws or belt drives, mechanical rolling ring drives also offer higher load capacity and longer life expectancy. This is due to the robust construction of the rolling ring bearing, which can withstand heavy loads and repeated use without compromising performance.

In terms of cost, mechanical rolling ring drives may have a higher initial investment compared to other types of mechanical drives. However, the long-term benefits of their precision, efficiency, and durability often outweigh the upfront cost. In many cases, the total cost of ownership for a mechanical rolling ring drive can be lower than that of other types of mechanical drives.

Overall, mechanical rolling ring drives offer a unique combination of precision, compact design, efficiency, and durability that make them a preferred choice for many applications. While they may not be suitable for every situation, their advantages make them a valuable option for industries that require reliable and accurate linear motion.

In conclusion, mechanical rolling ring drives stand out among other types of mechanical drives for their precision, compact design, efficiency, and durability. Their unique features make them a preferred choice for applications where accuracy and reliability are paramount. While they may have a higher initial cost, the long-term benefits of mechanical rolling ring drives often make them a cost-effective solution in the long run.