Table of Contents

Advantages of Using Rolling ring linear drive Motion in Industrial Automation

Rolling ring linear drive motion is a type of linear motion system that is commonly used in industrial automation applications. This technology offers several advantages over other types of linear motion systems, making it a popular choice for many industries.

One of the key advantages of rolling ring linear drive motion is its simplicity. Unlike other linear motion systems that use complex mechanisms and components, rolling ring Linear drives consist of just a few basic parts. This makes them easy to install and maintain, reducing downtime and increasing overall efficiency.

Another advantage of rolling ring linear drive motion is its high precision. These systems are capable of achieving extremely accurate positioning, making them ideal for applications that require precise control over movement. This level of precision is essential in industries such as manufacturing, where even small errors in positioning can lead to costly mistakes.

In addition to their precision, rolling ring linear drives also offer high repeatability. This means that once a position has been set, the system will be able to return to that position reliably and consistently. This is important in industrial automation applications where repetitive movements are common, as it helps to ensure that processes are carried out accurately and efficiently.

Rolling ring linear drives are also known for their durability and reliability. These systems are designed to withstand the rigors of industrial environments, including exposure to dust, dirt, and other contaminants. This makes them ideal for use in harsh conditions where other types of linear motion systems may struggle to perform.

Furthermore, rolling ring linear drives are highly versatile. They can be easily adapted to suit a wide range of applications, making them a flexible choice for industrial automation projects. Whether you need to move heavy loads, achieve high speeds, or operate in tight spaces, rolling ring linear drives can be customized to meet your specific requirements.

One of the key benefits of using rolling ring linear drive motion in industrial automation is its cost-effectiveness. These systems are typically more affordable than other types of linear motion systems, making them a cost-effective choice for businesses looking to improve their automation processes without breaking the bank.

Overall, rolling ring linear drive motion offers a range of advantages that make it an attractive option for industrial automation applications. From its simplicity and precision to its durability and cost-effectiveness, this technology has a lot to offer businesses looking to streamline their processes and improve efficiency. Whether you are looking to upgrade an existing system or implement a new automation solution, rolling ring linear drives could be the perfect choice for your needs.

How to Optimize Performance and Efficiency of Rolling Ring Linear Drive Motion Systems

Rolling ring linear drive motion systems are a popular choice for applications that require precise linear motion. These systems are known for their simplicity, reliability, and cost-effectiveness. However, in order to optimize the performance and efficiency of rolling ring linear drive motion systems, it is important to understand how they work and how to properly maintain them.

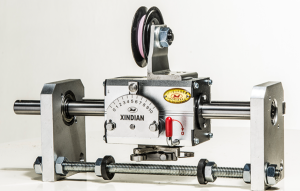

Rolling ring linear drive motion systems consist of three main components: a rolling ring, a nut, and a shaft. The rolling ring is a flexible metal band with a series of teeth on the inside. The nut is a cylindrical piece that fits over the rolling ring, and the shaft is the component that the nut moves along to create linear motion.

The rolling ring linear drive motion system works by rotating the nut, which causes the teeth on the inside of the rolling ring to engage with the teeth on the shaft. As the nut rotates, the rolling ring is forced to move along the shaft, creating linear motion. This simple yet effective design allows for precise and smooth linear motion in a variety of applications.

In order to optimize the performance of a rolling ring linear drive motion system, it is important to properly maintain the system. Regular cleaning and lubrication of the components can help to prevent wear and ensure smooth operation. It is also important to regularly check for any signs of damage or wear on the rolling ring, nut, and shaft, and replace any components that show signs of wear.

Another way to optimize the performance of a rolling ring linear drive motion system is to properly align the components. Misalignment of the rolling ring, nut, and shaft can cause uneven wear and reduce the efficiency of the system. By ensuring that the components are properly aligned, you can help to maximize the performance and efficiency of the system.

In addition to proper maintenance and alignment, choosing the right components for your rolling ring linear drive motion system can also help to optimize performance. High-quality rolling rings, nuts, and shafts can help to ensure smooth operation and long-lasting performance. It is important to choose components that are designed for your specific application and that meet the requirements of your system.

When it comes to optimizing the efficiency of a rolling ring linear drive motion system, there are a few key factors to consider. One important factor is the speed at which the system operates. By adjusting the speed of the system to match the requirements of your application, you can help to maximize efficiency and reduce energy consumption.

Another factor to consider when optimizing the efficiency of a rolling ring linear drive motion system is the load that the system is carrying. By properly sizing the components of the system to match the load requirements, you can help to ensure that the system operates efficiently and effectively.

In conclusion, rolling ring linear drive motion systems are a versatile and reliable choice for applications that require precise linear motion. By understanding how these systems work and how to properly maintain them, you can optimize the performance and efficiency of your system. By following these tips and best practices, you can ensure that your rolling ring linear drive motion system operates at its best for years to come.