Table of Contents

Advantages of Rolling ring linear drive Motion

Rolling ring linear drive motion is a unique and innovative technology that offers a wide range of advantages in various applications. This type of motion system is based on the principle of rolling rings that are used to transmit linear motion. In this article, we will explore the advantages of rolling ring linear drive motion and how it can benefit different industries.

One of the key advantages of Rolling ring drive motion is its simplicity and ease of use. Unlike other linear motion systems that require complex mechanisms and components, rolling ring Linear drives are relatively simple and easy to install. This makes them ideal for applications where space is limited or where a compact and lightweight solution is required.

Another advantage of rolling ring linear drive motion is its high precision and accuracy. The rolling rings used in this type of motion system are designed to provide smooth and precise linear motion, making them ideal for applications that require high levels of accuracy. Whether it’s in manufacturing, robotics, or medical devices, rolling ring linear drives can deliver the precision needed for a wide range of applications.

In addition to precision, rolling ring linear drive motion also offers high repeatability. The rolling rings used in this type of motion system are designed to provide consistent and repeatable linear motion, ensuring that the system can perform reliably over time. This makes rolling ring linear drives ideal for applications that require consistent performance and reliability.

Furthermore, rolling ring linear drive motion is known for its high efficiency. The rolling rings used in this type of motion system are designed to minimize friction and wear, resulting in a more efficient and energy-saving solution. This can lead to cost savings in the long run, as the system requires less maintenance and consumes less energy compared to other linear motion systems.

Another advantage of rolling ring linear drive motion is its versatility. This type of motion system can be easily customized to meet the specific requirements of different applications. Whether it’s in terms of speed, load capacity, or stroke length, rolling ring linear drives can be tailored to suit a wide range of applications.

Moreover, rolling ring linear drive motion is known for its durability and longevity. The rolling rings used in this type of motion system are made from high-quality materials that are designed to withstand the rigors of continuous use. This makes rolling ring linear drives a reliable and long-lasting solution for a wide range of applications.

In conclusion, rolling ring linear drive motion offers a wide range of advantages that make it an ideal choice for various industries. From its simplicity and ease of use to its high precision, repeatability, efficiency, versatility, durability, and longevity, rolling ring linear drives have a lot to offer. Whether it’s in manufacturing, robotics, medical devices, or any other application that requires linear motion, rolling ring linear drives can provide the performance and reliability needed to get the job done.

Applications of Rolling Ring Linear Drive Motion

Rolling ring linear drive motion is a unique and innovative technology that has a wide range of applications across various industries. This type of motion system utilizes a rolling ring drive mechanism to convert rotary motion into linear motion, providing precise and efficient movement in a compact design. In this article, we will explore some of the key applications of rolling ring linear drive motion and how it is revolutionizing the way we approach automation and motion control.

One of the most common applications of rolling ring linear drives motion is in the field of automation. This technology is often used in automated assembly lines, where precise and repeatable linear motion is required to move components from one station to another. The compact design of rolling ring linear drives makes them ideal for tight spaces, allowing for more efficient use of floor space in automated manufacturing environments.

Another key application of rolling ring linear drive motion is in the medical industry. This technology is often used in medical devices and equipment, such as robotic surgery systems and diagnostic imaging machines. The precise and smooth linear motion provided by Rolling Ring Drives is essential for ensuring the accuracy and reliability of these critical medical devices, helping to improve patient outcomes and reduce the risk of human error.

Rolling ring linear drive motion is also widely used in the packaging industry, where it is used to move products along conveyor belts and packaging lines. The high-speed and precise motion provided by rolling ring drives helps to increase the efficiency of packaging operations, allowing for faster production speeds and reduced downtime. This technology is also used in sorting and distribution systems, where it is essential for accurately sorting and moving packages to their designated locations.

In the aerospace and defense industries, rolling ring linear drive motion is used in a variety of applications, including aircraft control systems, missile guidance systems, and unmanned aerial vehicles. The high precision and reliability of rolling ring drives make them ideal for these critical applications, where safety and accuracy are paramount. This technology is also used in space exploration, where it is used to control the movement of robotic arms and other equipment on spacecraft.

Rolling ring linear drive motion is also finding applications in the field of robotics, where it is used to control the movement of robotic arms, grippers, and other components. The precise and smooth motion provided by rolling ring drives is essential for ensuring the accuracy and efficiency of robotic systems, allowing for more precise control and manipulation of objects in a variety of applications.

Overall, rolling ring linear drive motion is a versatile and innovative technology that is revolutionizing the way we approach automation and motion control. From automated manufacturing to medical devices to aerospace and defense, this technology is finding applications in a wide range of industries, helping to improve efficiency, accuracy, and reliability in a variety of applications. As technology continues to advance, rolling ring linear drive motion will likely play an increasingly important role in shaping the future of automation and motion control.

How Rolling Ring Linear Drive Motion Works

Rolling-ring drives motion is a unique and efficient method of converting rotary motion into linear motion. This technology is widely used in various industries, including automation, packaging, and medical devices. In this article, we will explore how rolling ring linear drive motion works and its advantages over other linear motion systems.

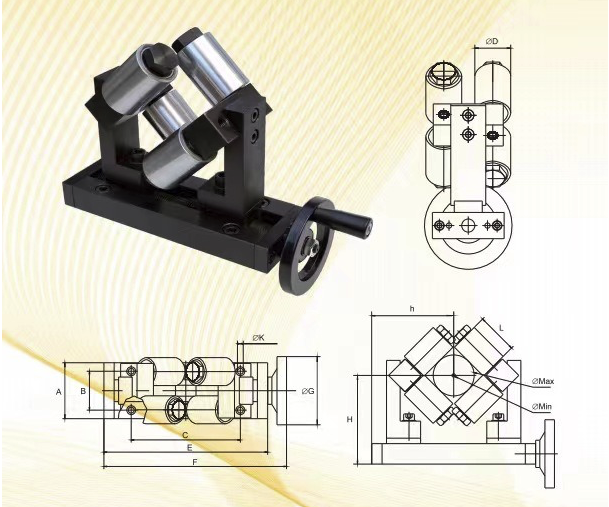

At the heart of rolling ring linear drive motion is a rolling ring bearing, also known as a slip ring or a traverse ring. This bearing consists of three precision-ground steel rings that are assembled in a specific configuration. The inner ring is fixed, while the middle ring is free to rotate around the inner ring. The outer ring is connected to the load that needs to be moved in a linear direction.

When a rotary motion is applied to the inner ring, it causes the middle ring to rotate. The rotation of the middle ring creates a frictional force between the rings, which in turn causes the outer ring to move linearly along the axis of the bearing. This linear motion can be controlled and adjusted by changing the speed and direction of the rotary input.

One of the key advantages of rolling ring linear drive motion is its simplicity and reliability. Unlike other linear motion systems that rely on complex mechanisms such as ball screws or linear motors, rolling ring bearings have fewer moving parts and are less prone to wear and tear. This results in lower maintenance costs and longer service life.

Another advantage of rolling ring linear drive motion is its high efficiency. The frictional force between the rings allows for smooth and precise linear motion without the need for additional lubrication or cooling systems. This makes rolling ring bearings ideal for applications where cleanliness and precision are critical, such as in cleanroom environments or medical devices.

Rolling ring linear drive motion is also highly customizable and can be tailored to meet specific application requirements. The speed, stroke length, and load capacity of the system can be easily adjusted by changing the size and configuration of the rolling ring bearing. This flexibility makes rolling ring bearings suitable for a wide range of applications, from small-scale automation to heavy-duty industrial machinery.

In conclusion, rolling ring linear drive motion is a versatile and efficient technology that offers numerous advantages over traditional linear motion systems. Its simplicity, reliability, and high efficiency make it an ideal choice for a wide range of applications in various industries. Whether you need precise and smooth linear motion for packaging machines, medical devices, or automation systems, rolling ring linear drive motion can provide the solution you need.